1 - 10 of 41

surface defect detection flaw detector

Selling leads|

...flaw detector easy to carry for metal pipe bar, wire, steel pipe, steel bar, copper wire, aluminum wire online, offline flaw detection, available ...

2025-08-01 16:02:24

|

|

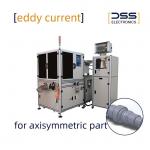

...detecting surface and near-surface defects in metals. It utilizes the principle of electromagnetic induction to generate eddy currents in the test ...

2025-08-02 00:16:17

|

|

..., compact size, light weight and convenient carrying. It is suitable for the magnetic particle detection of surface and near surface defects of ...

2025-07-25 11:38:50

|

|

... (NDT) device designed to inspect the quality and integrity of bearing rollers. It utilizes eddy current testing (ECT) technology to detect surface ...

2025-08-02 00:16:17

|

|

...Flaw Detector Copper Wire Aluminum Wire Descriptions FET-1.0 Digital Intelligence Eddy Current Detector is a high-precision, non-destructive ...

2025-08-02 00:16:17

|

|

... with high accuracy. The Ultrasonic Flaw Detector is equipped with a scanning angle of 0-180°, a rechargeable lithium battery as its power supply, ...

2025-08-01 16:02:50

|

|

... (NDT) device designed to detect surface and subsurface defects in conductive materials. By utilizing eddy current principles, the machine induces ...

2025-08-02 00:16:17

|

|

... such as copper clad aluminum, copper clad steel and other wire composite wire. It can effectively detect the defects such as aluminum exposure on ...

2025-08-02 00:16:17

|

|

... flaw detector Scanning range 2-4500mm Operating frequency 2-7.5 MHz Descriptions The HY20 portable digital ultrasonic flaw detector can quickly, ...

2025-08-02 00:16:17

|

|

...Flaw Detector Online And Offline Discriptiions FET-9HP intelligent digital Portable eddy current flaw detector is convenient to carry, suitable for ...

2025-08-02 00:16:17

|