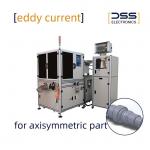

Automatic bearing roller eddy current flaw detector

large-scale integrated circuit

Descriptions

SWT-602 bearing roller Eddy Current flaw detector is a

specialized non-destructive testing (NDT) device designed to

inspect the quality and integrity of bearing rollers. It utilizes

eddy current testing (ECT) technology to detect surface and

sub-surface defects, such as cracks, inclusions, and other material

irregularities that could affect the performance of the rollers in

service.

SWT-602 bearing roller Eddy Current flaw detector operates

by inducing eddy currents in the bearing roller through a rapidly

alternating magnetic field. As the roller moves past the eddy

current probe, these induced currents flow through the material.

Any surface or sub-surface defect alters the flow of these

currents, producing a detectable signal change. The changes are

analyzed by the machine's software, which interprets the data to

determine the presence and characteristics of defects.

SWT-602 bearing roller eddy current flaw detector

is a fully automatic inspection machine which adopts large-scale

imported integrated circuit, combined with the most advanced eddy

current technology and microcomputer control. Equipped with a

perfectly designed mechanical transmission device, the formation of

a complete mechatronics system, is the only complete set of

complete system bearing roller automatic flaw detection machine.

The software written by WINDOWS operating platform makes the

instrument more convenient and intelligent. The performance of the

instrument is stable and reliable, which is suitable for the

bearing manufacturing industry to detect the cracks formed by the

raw material quenching and grinding of the bearing roller. Compared

with the magnetic powder flaw detector, it has the advantages of

high automation, fast detection speed, convenient inspection

process and no human factors. It is the most ideal equipment for

the inspection of the bearing roller.

Specifications

SWT-602 bearing roller eddy current flaw detector| Frequency Range | 64Hz- 4MHz | | Gain range | 0-90dbcontinuously adjustable, step: 0.5dB | | Phase rotation | 0 ~ 360° continuously adjustable, step: 1 Deg | | Gain ratio | (Y/X) 0.1 ~ 10.0 | | Detection speed | ≤ 6 m/s | | Operating voltage | AC220±10V | | Operating Temperature | Tippically from -15°C to + 55°C | | Storage temperature | Tippically from -20℃ to +60℃ | | Detection capability | Can detect 0.03mm deep crack | | Equipment noise | <60db | | Power dissipation | <500W(220V)

| | Relative humidity | Not more than 85% | | Detection object | Cylindrical roller, conical roller, needle roller, pin |

| |

Other descriptions

1,SWT-602 bearing roller eddy current flaw detector uses two

independent ways to detect the workpiece (i.e. one tow two).

2,After inspection, there is no need for demagnetization, cleaning

and other auxiliary processes.

3,SWT-602 bearing roller eddy current flaw detector automatically

feeds, sorts and counts.

SWT-602 type bearing roller eddy current inspection machine working

site diagram