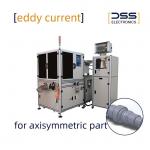

Eight Channels Microcomputer-controlled Eddy Current Flaw Detector

Axisymmetric Part

Descriptions

SWT-618 microcomputer-controlled eddy current flaw

detector is an advanced non-destructive testing (NDT) device

designed to detect surface and subsurface defects in conductive

materials. By utilizing eddy current principles, the machine

induces currents in the material and monitors their interaction

with imperfections such as cracks, corrosion, or material property

changes. The system is equipped with a microcomputer that automates

the control, data acquisition, signal processing, and analysis,

offering enhanced accuracy and ease of use. The device is widely

used in industries like aerospace, automotive, manufacturing, and

power generation.

The system consists of a probe, signal generator, signal processor,

and a microcomputer that provides real-time feedback and analysis

through graphical displays. Operators can adjust test parameters

for different materials and defect detection requirements, ensuring

flexibility and customization in various inspection scenarios.

SWT-618 microcomputer-controlled eddy current flaw detector

is a fully automatic mechatronics inspection machine which combines

the most advanced eddy current technology and microcomputer

control. SWT-618 microcomputer-controlled eddy current flaw

detector has powerful function, simple and intelligent

operation, high degree of automation, can effectively detect and

distinguish various defects in real time, and has the advantages of

beautiful shape, reasonable structure and compact. The software

written by WINDOWS operating platform makes the instrument more

convenient and intelligent.

Specifications

SWT-618 microcomputer-controlled eddy current flaw detector| Channel | 8 | | Detection object | axisymmetric parts(⌀ 12mm ~ ⌀30mm) | | Detection speed | <2 seconds/piece | | Sorting speed | Not less than 50 pieces/min | | Frequency Range | 100Hz-10MHz(adjustable based on material) | | Gain range | 0-70dbcontinuously adjustable, step: 0.5dB | | Phase rotation | 0 ~ 360° continuously adjustable, step: 1 Deg | | Operating voltage | AC220±10 v | | Operating Temperature | Tippically from -10°C to + 55°C | | Storage temperature | Tippically from -20℃ to +60℃ | | Relative humidity | Not more than 85% | | Power dissipation | < 400 w (220 v) | | Sampling rate | 16 x 2500 times/second | | Detection capability | Crack (length >0.05mm, depth >2mm) |

|

|

Other descriptions

1,SWT-618 microcomputer-controlled eddy current flaw detector uses a point differential eight-channel array probe.

2,SWT-618 microcomputer-controlled eddy current flaw detector‘s detection surface is the outer diameter and the end face.

3,SWT-618 microcomputer-controlled eddy current flaw detector is automatic feeding, automatic sorting, automatic counting.

SWT-618 microcomputer-controlled eddy current flaw detector

’operating picture