X52 Cladding Inconel 625 Weld Overlay Carbon Steel Seamless Pipe API 5L

|

Detailed Product Description

|

Carbon Steel Seamless Pipe API 5L X65 Cladding Inconel 625 Weld Overlay

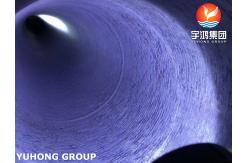

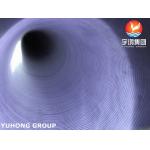

A carbon steel seamless pipe with API 5L X65 base material and

Inconel 625 weld overlay cladding is a high-performance

engineered pipe designed for extreme environments, combining the

strength of carbon steel with the corrosion/erosion resistance of a

nickel-chromium alloy. Key Specifications & Features 1. Base Material: API 5L X65 Seamless Pipe - Grade: API 5L X65 (PSL1 or PSL2) - Yield Strength:65,000 psi (448 MPa) min - Manufacturing: Hot-rolled or cold-drawn seamless process (no

welds, superior pressure integrity). - Applications: Oil & gas pipelines, downhole tubing,

high-pressure hydraulic systems. 2. Cladding: Inconel 625 Weld Overlay - Alloy Composition (UNS N06625): - Ni (58% min), Cr (20–23%), Mo (8–10%), Nb+Ta (3.15–4.15%) - Resistant to pitting, chloride stress corrosion cracking (SCC),

and oxidation up to **1800°F (982°C). Cladding Methods: - Laser Cladding (Precision, Low Dilution) - Submerged Arc Welding (SAW) or GTAW (TIG) Overlay - Thermal Spray (Less Common for Pipes) - Thickness: Typically 3–5 mm (customizable based on

corrosion/erosion needs). Why Use Inconel 625 Over API 5L X65? Corrosion Resistance: Protects against H₂S, CO₂, seawater, and

acidic fluids. Erosion Resistance: Ideal for sand-laden fluids (e.g.,

fracking, slurry transport). High-Temp Performance: Maintains strength in

refinery/petrochemical heat exchangers. Cost-Effective: Cheaper than solid Inconel 625 pipe but offers

similar protection. Manufacturing Process 1. Pipe Production: Seamless API 5L X65 pipe is manufactured

via mandrel piercing/extrusion. 2. Surface Prep: Internal/external surface grit

blasting/cleaning. 3. Cladding:*Inconel 625 is welded layer-by-layer (buttering

passes) to ensure metallurgical bonding. 4. Post-Weld Heat Treatment (PWHT): Optional stress relief

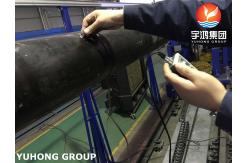

(avoid if base metal is cold-worked). 5. Inspection: - UT/RT for weld integrity. - Hardness Testing (avoid HAZ cracking). - Dye Penetrant (PT) for surface defects. Applications - Oil & Gas - Subsea pipelines (clad internally for sour service). - Christmas trees, choke valves, risers. - Chemical Processing: Acid transport, reactor liners. - Power Plants: Boiler tubes, flue gas desulfurization (FGD)

systems. - Mining:Slurry pipelines with abrasive/acidic media. Challenges & Solutions - Galvanic Corrosion Risk:*Insulate clad pipe from dissimilar

metals (e.g., CS flanges). - Weld Defects: Strict NDT (radiographic testing) to ensure

clad adhesion. - Thermal Expansion: Inconel 625 (~13.3 µm/m°C) vs. CS (~11.7

µm/m°C)—design for differential expansion. |

| Product Tags: Inconel 625 Weld Overlay Pipe Carbon Steel Seamless Pipe X52 Seamless Pipe API 5L X52 |

Related Products

|

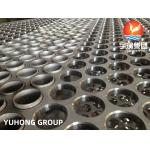

Weld overlay Tubesheet , ASTM A266 Gr.2 CS Tube Sheet Cladding Stainless Steel |

|

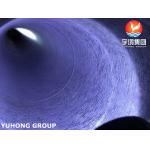

X52 Cladding Inconel 625 Weld Overlay Carbon Steel Seamless Pipe API 5L |

|

Cladding API 5L X65 Carbon Steel Seamless Pipe Cladded With Inconel 625 |

|

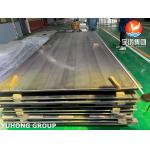

Explosive Clad Plate ASME SA516 Gr.70 Carbon Steel Cladding ASME SB127 Monel 400 |

|

Carbon Steel Cladding Plate A516 Gr 70 With N04400 One Side Explosive Composite |

|

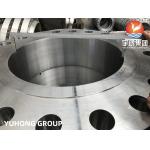

Inconel 625 Cladding Flange ASTM A694 F52 Carbon Steel Cladding Weld Neck Flange |

Email to this supplier