Carbon Steel Cladding Plate A516 Gr 70 With N04400 One Side Explosive Composite

|

Detailed Product Description

|

CARBON STEEL CLADDING PLATE A516 GR.70 WITH N04400 ONE SIDE CLADDING

Explosive Composite Steel Plate (Explosion-Welded Clad Plate) Explosive composite steel plate, also known as explosion-welded

clad plate, is a high-performance material created by bonding two

or more dissimilar metals using controlled detonation. This process

forms a metallurgical bond without significantly altering the

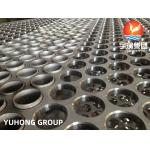

properties of the base metals. 1. How Explosive Cladding Works The process involves: - Base Plate (Backing Metal): Typically carbon steel (e.g., A516

Gr.70) or low-alloy steel. - Clad Layer (Corrosion-Resistant Metal): Such as Monel 400

(N04400), stainless steel, titanium, or nickel alloys. - Explosive Material: A high-energy explosive (e.g., RDX or

ammonium nitrate) is placed over the clad layer. - Detonation: When ignited, the explosion creates extreme pressure

(up to 10 GPa) and high velocity (hundreds to thousands of m/s),

forcing the two metals to collide at an angle, creating a

metallurgical bond. 2. Advantages of Explosive Clad Plates Strong Bonding: Higher shear strength than roll-bonded or

weld-overlay cladding. Wide Material Combinations: Compatible with metals that are

otherwise difficult to weld (e.g., steel + titanium, steel +

copper). No Intermetallic Brittleness: Unlike fusion welding, explosion

welding avoids harmful phases. Thickness Flexibility: Clad layer can range from 1mm to 30mm. Cost-Effective: Saves expensive alloys by using them only where

needed. 3. Applications of Explosive Composite Plates - Oil & Gas: Pressure vessels, pipelines, offshore platforms. - Chemical Processing: Reactors, heat exchangers, acid storage

tanks. - Power Plants: FGD systems, condenser tubes. - Marine & Desalination: Seawater handling equipment. - Aerospace & Defense: Lightweight armor, rocket components.

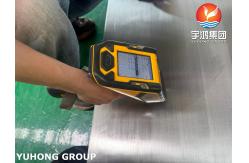

5. Common Explosive Clad Combinations - Carbon Steel + Stainless Steel (304/316) - A516 Gr.70 + Monel 400 (N04400) - Steel + Titanium (Gr.2/Gr.5) - Steel + Copper/Nickel Alloys 6. Standards & Testing - ASTM B898 (Explosion-welded clad plates) - ASME SA264 (Stainless-clad steel plate) - ISO 23206 (Explosive welding) - Non-Destructive Testing (NDT): Ultrasonic testing (UT),

radiography (RT). |

||||||||||||||||||

| Product Tags: Explosive composite Cladding Plate One Side Explosive Cladding Plate Explosive composite N04400 Cladding Plate |

Related Products

|

Weld overlay Tubesheet , ASTM A266 Gr.2 CS Tube Sheet Cladding Stainless Steel |

|

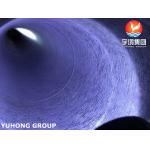

X52 Cladding Inconel 625 Weld Overlay Carbon Steel Seamless Pipe API 5L |

|

Cladding API 5L X65 Carbon Steel Seamless Pipe Cladded With Inconel 625 |

|

Explosive Clad Plate ASME SA516 Gr.70 Carbon Steel Cladding ASME SB127 Monel 400 |

|

Carbon Steel Cladding Plate A516 Gr 70 With N04400 One Side Explosive Composite |

|

Inconel 625 Cladding Flange ASTM A694 F52 Carbon Steel Cladding Weld Neck Flange |

Email to this supplier