Cladding API 5L X65 Carbon Steel Seamless Pipe Cladded With Inconel 625

|

|

API 5L X65 Cladding Pipe Carbon Steel Seamless Pipe Cladded with Inconel 625

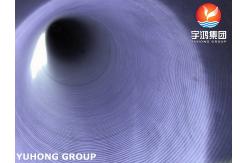

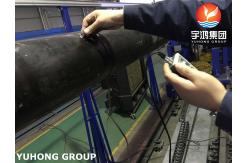

API 5L X65 carbon steel seamless pipe, internally clad with a metallurgically bonded layer of Inconel 625, combines the high strength and cost-effectiveness of the steel substrate with the exceptional corrosion, erosion, and temperature resistance of the nickel alloy liner. This bifunctional design provides durable, economical performance in demanding environments (e.g., sour service, subsea flowlines, acid injection, high-chloride process piping) where solid alloy construction is cost-prohibitive and bare carbon steel would fail.

API 5L X65 Carbon Steel Seamless Pipe Cladded with Inconel 625

API 5L Line Pipe Chemical Composition and Mechanical Propertity

Key Purpose of Cladding:

When to Use Cladding vs. Solid Alloy? Advantages? 1>. Cladding: High-pressure vessels, heat exchangers, large

structures needing corrosion resistance. For specific project needs (e.g., temperature, acid concentration), consult corrosion charts to select the optimal cladding alloy!

Applications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Cladding Carbon Steel Seamless Pipe API 5L X65 Pipe Cladded Inconel 625 Pipe | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

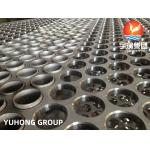

Weld overlay Tubesheet , ASTM A266 Gr.2 CS Tube Sheet Cladding Stainless Steel |

|

X52 Cladding Inconel 625 Weld Overlay Carbon Steel Seamless Pipe API 5L |

|

Cladding API 5L X65 Carbon Steel Seamless Pipe Cladded With Inconel 625 |

|

Explosive Clad Plate ASME SA516 Gr.70 Carbon Steel Cladding ASME SB127 Monel 400 |

|

Carbon Steel Cladding Plate A516 Gr 70 With N04400 One Side Explosive Composite |

|

Inconel 625 Cladding Flange ASTM A694 F52 Carbon Steel Cladding Weld Neck Flange |