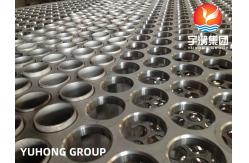

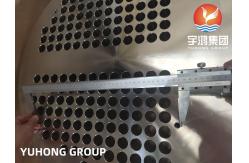

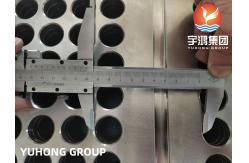

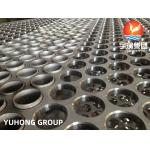

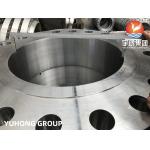

Weld overlay Tubesheet , ASTM A266 Gr.2 CS Tube Sheet Cladding Stainless Steel

|

|

ASTM A266 Gr.2 Carbon Steel Cladding SS316L Tubesheet For Pressure Vessel

Weld overlay (also known as cladding, hardfacing, or surfacing) offers several significant advantages over using solid alloy materials or other coating techniques, making it a widely adopted process in industries like oil & gas, power generation, mining, chemical processing, and heavy manufacturing.

Carbon steel can be clad with a variety of materials depending on the intended application. Some commonly used cladding materials for carbon steel include stainless steel, nickel alloys, copper alloys, and titanium. The choice of cladding material will depend on factors such as the desired corrosion resistance, mechanical properties, and cost. For example, stainless steel is often used to clad carbon steel in applications where corrosion resistance is important, while nickel alloys are commonly used in high-temperature environments. We can supply various caldding products, including pipe, fitting, flange and dished end.

Overlay welding involves depositing a layer of weld material onto the surface of a base metal. This is typically done using a welding process such as TIG or MIG welding. The purpose of overlay welding is to improve the corrosion resistance or wear resistance of the base metal. This method is commonly used in applications such as oil and gas pipelines, where corrosion resistance is critical. Explosive cladding, on the other hand, involves using explosives to bond two or more metals together. In this process, the two metals are placed in contact with each other and an explosive charge is detonated, causing the metals to bond together at high velocity. This method is often used to join dissimilar metals together, such as aluminum and steel, and can produce a metallurgical bond that is very strong. Advantages of using cla overlay materials 1. Cost Savings (Major Advantage):

2. Enhanced Corrosion Resistance:

3. Superior Wear Resistance:

Applications Marine Engineering Shipbuilding Heat Exchanger Equipment Petroleum Refining Power Plant Chemical Processing Oil and Gas

|

|||||||||||||||||||||||||

| Product Tags: Carbon Steel Clad Tube Sheet SS316L Clad Tube Sheet |

|

Weld overlay Tubesheet , ASTM A266 Gr.2 CS Tube Sheet Cladding Stainless Steel |

|

X52 Cladding Inconel 625 Weld Overlay Carbon Steel Seamless Pipe API 5L |

|

Cladding API 5L X65 Carbon Steel Seamless Pipe Cladded With Inconel 625 |

|

Explosive Clad Plate ASME SA516 Gr.70 Carbon Steel Cladding ASME SB127 Monel 400 |

|

Carbon Steel Cladding Plate A516 Gr 70 With N04400 One Side Explosive Composite |

|

Inconel 625 Cladding Flange ASTM A694 F52 Carbon Steel Cladding Weld Neck Flange |