LiTaO3 Wafer Lithium Tantalate Electro-Optic Nonlinear Optical Piezoelectric Customization

|

|

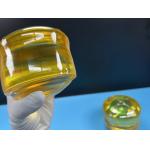

LiTaO3 Wafer Lithium Tantalate Electro-Optic Nonlinear Optical Piezoelectric Customization Introduce of LiTaO3 WaferLithium tantalate is an excellent multifunctional crystalline material characterized by its ilmenite-type structure, exhibiting a colorless or pale yellow appearance. Renowned for its abundant raw material availability, exceptional thermal and chemical stability, and machinability, lithium tantalate enables the growth of high-quality, large-dimensioned single crystals. When polished, these crystals demonstrate outstanding performance in the fabrication of electronic communication components such as resonators, surface acoustic wave (SAW) filters, and transducers. As an indispensable functional material, lithium tantalate plays a critical role in advanced communication technologies including mobile communications, satellite systems, and aerospace applications.

Technical Features of LiTaO3 Wafer (1) Electro-Optic Properties: Lithium tantalate exhibits remarkable electro-optic properties, which form the foundation for its applications in optical communications and computing. As a non-centrosymmetric crystal, lithium tantalate demonstrates a strong linear electro-optic (Pockels) effect. Under applied electric fields, its refractive index undergoes modulation, enabling efficient conversion of electrical signals into optical signal modulation.

(2) Photorefractive Effect: Lithium tantalate is highly photosensitive, even to weak light, which triggers significant photorefractive effects. Upon illumination, electrons in the material are excited from the valence band to the conduction band, leaving behind an equivalent number of holes. Free charges migrate under electric fields, forming spatial charge distributions that alter the internal electric field and induce refractive index changes. Notably, this photorefractive effect is typically reversible; once illumination ceases, the refractive index partially or fully recovers to its original state.

(3) Piezoelectric Effect: Belonging to the trigonal crystal system, lithium tantalate features a non-centrosymmetric structure with misaligned positive and negative charge centers. When subjected to mechanical stress, displacement between these charge centers generates surface charges, manifesting as a piezoelectric response.

Principle of LiTaO3 Wafer

Chemical Vapor Deposition (CVD):

Lithium Tantalate (LiTaO₃) Material SpecificationsI. Basic PropertiesII. Bulk Crystal Specifications

III. Wafer Specifications

Application of LiTaO3 WaferPiezoelectric Resonators & Filters: Leveraging its strong piezoelectric effect, LiTaO₃ is used in high-frequency surface acoustic wave (SAW) filters and bulk acoustic wave (BAW) resonators for signal processing in mobile phones, satellite communications, and radar systems. Ultrasonic Transducers & Piezoelectric Imaging: High electromechanical coupling coefficient makes LiTaO₃ ideal for medical ultrasound imaging and industrial non-destructive testing transducers.

Q&A of LiTaO3 Wafer

Q: What is LiTaO₃?

Q: What’s the difference between LiTaO₃ and LiNbO₃?

Q: What are the typical crystal orientations of LiTaO₃?

Q: Can LiTaO₃ products be customized?

Related products High Purity Silicon Carbide Wafer Prime/Dummy/Ultra Grade 4H-Semi SiC Wafers For 5G Device Sapphire wafer 2inch C-plane(0001) DSP SSP 99,999% Monocrystalline Al2O3 LEDS Semiconductor

|

| Product Tags: Electro Optic LiTaO3 Wafer Piezoelectric LiTaO3 Wafer Nonlinear Optical LiTaO3 Wafer |

|

|

Semi Insulating GaN-On-Silicon Wafer Free Standing Gallium Nitride Substrates |

|

1inch 2inch Beta Coefficient Ga2O3 Gallium Oxide Wafer Substrate Dsp Ssp |

|

Beta Coefficient-Ga2O3 Gallium Oxide Wafer Doped Mg Fe3+ Square Substrate Dsp Ssp |

|

|

Large Thickness SiO2 Thermal Oxide On Silicon Wafers For Optical Communication System |

|

Y-42 Degree 4inch Lithium Tantalate LiTaO3 LiNbO3 Lithium Niobate Crystal Raw Unprocessed Ingots |

|

Single Crystal InP Indium Phosphide Wafers 350 - 650um Thickness |