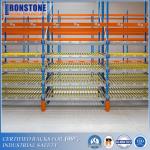

Customized Dynamic Gravity Carton Flow Storage Rack

|

|

Customized Dynamic Gravity Carton Flow Storage Rack

Carton flow racking can be a standalone unit or a fully integrated system that follows the first-in, first-out (FIFO) inventory management principle. Many of these systems include pallet storage at the top of the rack as well as carton-picking capabilities on the bottom half. When a worker removes a carton from the storage rack, the next carton automatically moves to the front, reducing retrieval times and increasing process efficiency.

Because they reduce the strains associated with repetitive bending, reaching, and pulling, these systems are ideal for increasing the safety levels of an operation. The improved organization also increases the overall storage space in your facility. Warehousing and distribution, light assembly, food and beverage, medical manufacturing, and commercial printing are a few examples of industries that use these systems.

Features & Benefits of Carton Flow Warehouse Racking:

1.First-in/first-out picking results in a perfect turnover. 2.Simple access to reserved products stored behind each carton /

container. 3.Easy dismantling and reconfiguration of gravity flow rack systems

within the same warehouse or other facilities. 4.Reduction in the time required to prepare an order or pick

assembly parts. 5.Extended storage capacity. 6.Allows restocking and picking operations to operate independently

and without interference. A carton flow racking system is advantageous to your warehouse for

a variety of reasons. Because it allows your load to move to the

front of the rack on its own as the preceding products are picked,

this storage system is considered dynamic rather than static. This

saves your crew time and effort by eliminating the need for

bending, reaching, and pulling when picking. Furthermore, carton

flow racking makes the most of your available storage space.

Overall, carton flow racking makes your storage facility much more

efficient.

Carton Flow Racking Components Carton flow racking is similar to traditional, static storage

systems in that both start with basic units that can be expanded as

needed. The roller track, which allows your products to shift

forward as they are picked, is the most important component of a

carton flow racking system. A carton flow racking system's frames

are typically designed as either layback or square front. The

square front frame is useful for heavy products, while layback

improves access and visibility.

Carton Flow Pallet Racking is ideal for high-volume picking

operations such as: ►Warehouses for mass-consumption products. ►Pharmaceuticals and cosmetics. ►Articles on IT and the automobile industry. ►Create buffer warehouses between two work points. ►Areas with assembly lines. IRONSTONE Quality certificates of Carton Flow Rack storage system:

♦ISO 9001: 2008

♦ISO 18001: 2004

♦OSHAS 18001: 2007

♦Welding certificate: UNE EN ISO 3834-2: 2006

♦Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

♦Galvanized steel reaction to fire: EN 13501-1: 2007

Our products have passed the AS4084 testing in Australia, the strictest safety norm in the racking line. At the same time, the products completely comply with this strict standard FEM 10.2.02 in Europe, and international markets approve our products. |

||||||||||||||||||||||||||||||||||||||||

| Product Tags: Carton Flow Storage Rack Gravity Carton Flow Storage Rack Dynamic Gravity Carton Flow Rack | ||||||||||||||||||||||||||||||||||||||||

|

Carton Gravity Flow Rack System Customized with FIFO |

|

Customized Dynamic Gravity Carton Flow Storage Rack |

|

FIFO Automatic Gravity Theory Carton Flow Racking System |

|

Multi-Level Gravity Carton Flow Logistic Rack For Reducing Damage |

|

Heavy Duty Pallet Racking Carton Flow System For Box Crates Overturn Storage |

|

High Efficient Carton Flow Racking With Continuous Inventory Rotation |