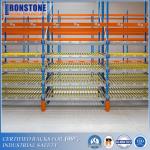

Multi-Level Gravity Carton Flow Logistic Rack For Reducing Damage

|

|

Multi-Level Gravity Carton Flow Logistic Equipment Warehouse Storage Roller Pallet Racking

Carton flow storage racking is frequently encountered in warehouses with high-volume order picking and a First-In/First-Out product rotation. The product (boxes or cartons) is loaded into these gravity-driven warehouse rack systems from the back, and it flows to the front of the rack system for picking and packing. These products often feature candy, small parts, or small boxes, as well as split cases and piece-choosing products.

To match your SKUs, custom-built span-track or carton flow storage systems can be created. A "psychologist" is a requirement when planning the layout of your warehouse because of the changeable shelf levels and many roller possibilities. Finding the ideal solution through application analysis is a specialty of our psychologists. Are you a distributor or producer of beer trying to maximize storage in your warehouse, increase productivity, and make your warehouse more ergonomic? Visit the webpage for Ironstone Storage.

How does Carton Flow Rack Works?

Benefits of Carton Flow

►Use of less floor space.

►Decreased labor costs.

►Minimal product harm.

►Improved inventory management.

►It can be utilized with pallet racks that are already in use.

►Less time spent working.

►Simple to modify or res lot.

Types of Carton Flow

♦ Roller Lanes

Roller lanes are frequently employed in activities that don't require a wide range of carton sizes and in applications that demand specialized lanes of carton flow.

♦ Wheel Beds

To evenly distribute the weight of the cartons throughout the bed, wheel beds often have a system of alternating or staggered wheels. This minimizes the possibility of imprinting by ensuring that no wheel or group of wheels bears more weight than the rest of the bed.

In contrast to full-width rollers, wheel beds can be positioned side by side, providing a continuous bed of carton flow across an entire level. Wheel beds are therefore perfect for operations where there is a lot of variation in carton sizes and where bays need to be re-slotted for a shifting product line.

♦ Tilted Shelving

Tilted shelves don't have a "dead zone," or a place at the back of the shelf that an order picker can't access, in contrast to flat, static shelving. As a result, order pickers won't have to use a shepherd's hook and won't participate in risky picking techniques like climbing a rack to get to a product in the dead zone.

Slow-moving SKUs are ideally suited for titled shelves. Tilted shelves are not the best option for SKUs that require frequent refilling because they are often much shallower in depth than roller lanes, wheel beds, and wheel rails.

♦ Wheel Rails

Wheel rails are wheels installed directly inside a channel, made of steel, aluminum, or plastic. Wheel rail versions come in a wide variety; some have wheels placed on separate axles, while others have rigid studs mounted inside the channel. Wheel rails can either have a single vertical line of wheels or an alternating wheel design. Due to the independence of one wheel rail from the next, the rails can be arranged and spaced differently.

Since wheel rails are not load-bearing, the rack must provide intermediate support. If the wheel rails within the rack are not parallel, containers like boxes and totes may become trapped on the rails. In order to prevent rail movement and carton imprinting, wheel rails are ultimately most effective when moving smaller, lighter cartons.

|

||||||||||||||||||||||||||||||||||||||||

| Product Tags: Multi Level Roller Pallet Racking Gravity Carton Roller Pallet Racking | ||||||||||||||||||||||||||||||||||||||||

|

Carton Gravity Flow Rack System Customized with FIFO |

|

Customized Dynamic Gravity Carton Flow Storage Rack |

|

FIFO Automatic Gravity Theory Carton Flow Racking System |

|

Multi-Level Gravity Carton Flow Logistic Rack For Reducing Damage |

|

Heavy Duty Pallet Racking Carton Flow System For Box Crates Overturn Storage |

|

High Efficient Carton Flow Racking With Continuous Inventory Rotation |