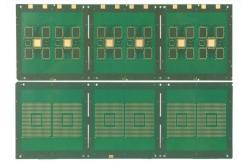

Multilayer IC Substrate PCB Board PCB Rigid Blind Vias Soft Gold

|

|

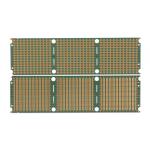

Product Images

About TECircuit

Found: TECircuit has been operating since 2004.

Product Applications

Product Features

FAQ Question 1: What is needed for a quotation? Product Description

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Multilayer IC Substrate PCB Board Soft Gold IC Substrate PCB Board | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

IC Substrate Multilayer Rigid PCB for Mobile Phone EMMC Package Substrate |

|

IC Substrate PCB Multilayer Rigid Printed Circuit Board LGA Package ENIG Finish |

|

Multilayer Rigid IC Substrate PCB Board Fingerprint Card Soft Gold Hard Gold |

|

IC Substrate Multilayer Rigid PCB MEMS Sensor Micro Electromechanical System |

|

IC Substrate Multilayer PCB , HDI Rigid PCB ENIG Surface for RF Module |

|

Multilayer IC Substrate PCB Board PCB Rigid Blind Vias Soft Gold |