In the domain of missiles and weapons, the margin for error is non

- existent. These high - stakes systems must function flawlessly

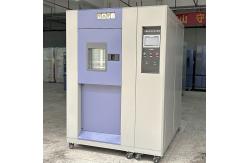

under the most extreme and variable environmental conditions. A

custom thermal humidity chamber designed specifically for missiles

and weapons offers a controlled environment to test, validate, and

optimize these critical systems. By simulating a wide range of

thermal and humidity conditions, it plays a pivotal role in

ensuring the reliability, performance, and safety of missiles and

weapons. - Wide - Range Temperature Control: The chamber is engineered to achieve a broad temperature

spectrum, typically from - 55°C to 150°C. This enables the

replication of frigid arctic conditions where missiles may be

stored or launched, as well as the intense heat generated during

high - speed flight or re - entry into the Earth's atmosphere. The

temperature control accuracy is within ±1°C, ensuring that the test

conditions closely mirror real - world scenarios. For instance, the

heat - resistant materials of a missile's nose cone can be

rigorously tested at extreme high temperatures to ensure they can

withstand the intense heat generated during atmospheric re - entry.

- Accurate Humidity Regulation: Humidity levels can be precisely adjusted from 10%RH to 98%RH.

High humidity can accelerate corrosion in metal components of

missiles and weapons, while sudden humidity changes can cause

condensation, leading to electrical malfunctions. With an accuracy

of ±2%RH, the chamber allows for the simulation of various humidity

- related challenges. For example, the electronic components inside

a missile can be tested in high - humidity conditions to evaluate

their resistance to moisture - induced short - circuits.

- Ample Space for Large - Scale Systems: The chamber is designed with a large interior volume to

accommodate full - scale missiles, large - caliber weapons, and

complex weapon systems. Custom - sized dimensions can be tailored

to specific requirements, with typical lengths ranging from 0.4

meters to 2 meters, widths from 0.4 meters to 2 meters, and

heights from 0.5 meters to 2 meters. This ensures that the entire

system, along with all its components and subsystems, can be

comprehensively tested.

- Flexible Fixturing and Mounting Options: To securely hold the missiles and weapons during testing, the

chamber is equipped with a variety of customizable fixturing and

mounting systems. These can be adjusted to support different

shapes, sizes, and weights of the test items. For example,

specialized cradles and brackets can be designed to hold a missile

in a launch - like position, allowing for easy access to its

components for inspection and data - collection purposes.

- Real - Time Data Acquisition: A comprehensive monitoring system is integrated into the chamber,

continuously collecting data on temperature, humidity, and other

critical parameters. Multiple sensors are strategically placed

inside the chamber to ensure accurate and comprehensive data

collection. For example, humidity sensors can be placed near the

missile's guidance system to monitor the moisture levels that could

potentially affect its performance, while temperature sensors can

be used to monitor the heat - sensitive components of a weapon's

firing mechanism.

- Automated Control and Adjustment: The chamber is equipped with an automated control system that

allows for precise control of all environmental parameters.

Operators can set complex test profiles, including ramping rates

for temperature and humidity changes, hold times at specific

conditions, and cycling sequences. The system can automatically

adjust the parameters based on pre - set algorithms, ensuring that

the test conditions are maintained within the desired tolerances

throughout the testing process.

| Specification Items | Details |

|---|

| Temperature Range | - 55°C to 150°C | |

|