In the realm of military technology, where reliability and

performance in extreme conditions are non-negotiable, the Custom

Thermal Shock Chambers designed to meet Military Standard 810G,

Method 509.5 test standards stand as a testament to precision

engineering and innovation. This custom-built thermal shock chamber is dedicated to subjecting

military equipment and components to the exacting thermal shock

testing requirements of Military Standard 810G, Method 509.5. It

serves a crucial role for defense contractors, military research

facilities, and the armed forces themselves. The primary aim is to

evaluate the ability of a wide range of items, from sensitive

electronics and optical systems to rugged mechanical assemblies, to

endure rapid and severe temperature changes. By replicating the

thermal shock scenarios that military assets may face during their

operational lifetimes, such as those encountered during rapid

altitude changes, transitions between different climate zones, or

in the vicinity of heat-generating equipment, manufacturers can

identify design weaknesses, optimize materials and manufacturing

processes, and enhance the overall durability and mission-readiness

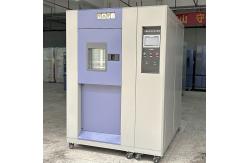

of military equipment. - Robust and Insulated Chamber Design

- The chamber is constructed with heavy-duty, heat-resistant

materials that can withstand the intense thermal stresses. The

walls are made of high-strength alloy steel, combined with advanced

thermal insulation layers to minimize heat transfer between the hot

and cold zones. The door is engineered with a reliable sealing

mechanism and a viewing window, allowing operators to monitor the

testing process without compromising the chamber's integrity. The

interior is designed with adjustable racks and fixtures, enabling

the accommodation of variously sized and shaped military components

and ensuring uniform exposure to the thermal shock conditions.

- Precision Temperature Control and Cycling System

- Temperature Range and Cycling: Capable of achieving a wide

temperature range, typically from -70°C to +150°C. The system can

execute rapid temperature cycling between the hot and cold zones,

with a transition time as short as a few seconds. This is essential

for mimicking the abrupt temperature changes that military

equipment may experience. The temperature control is accurate to

within ±0.2°C, providing highly reliable and repeatable test

results.

- Programmable Temperature Profiles: The chamber's control system

allows for the creation and execution of complex, custom

temperature profiles. Operators can define specific temperature

levels, dwell times in each zone, and the sequence and number of

thermal shock cycles to replicate a diverse range of real-world

military operational conditions. This flexibility enables

comprehensive testing of components under different

mission-critical scenarios.

- Intuitive Control Panel and Data Acquisition Interface

- The control panel is designed for ease of use by military

technicians and engineers. It offers a user-friendly interface that

allows effortless setting and adjustment of all test parameters,

including temperature, cycling times, and equipment identification.

The panel also provides real-time displays of the current

temperature in both zones, the status of the testing process, and

any alarms or warnings. The chamber is integrated with a

comprehensive data acquisition system that records all relevant

test data. This includes detailed temperature histories, cycle

counts, and any observable changes in the physical, electrical, or

mechanical properties of the tested components. The data can be

stored in a secure, encrypted format in the chamber's built-in

memory or exported to external military-approved storage devices

for in-depth analysis and reporting. The system can also generate

detailed test reports in various standardized military formats.

- Enhanced Safety and Security Features

- To ensure the safety of operators and the protection of sensitive

military test samples and the chamber itself, a suite of advanced

safety and security features is incorporated. These include

multiple layers of over-temperature and over-current protection,

emergency stop buttons with redundant circuitry, and alarms for any

abnormal temperature fluctuations, equipment malfunctions, or

security breaches. The chamber is also equipped with access control

mechanisms, such as biometric authentication or smart card readers,

to prevent unauthorized access and safeguard classified testing

activities. Additionally, it has a self-contained fire suppression

system and proper ventilation and exhaust mechanisms to handle any

potentially hazardous gases or vapors that may be generated during

testing.

- Temperature Range and Accuracy

- The -70°C to +150°C temperature range with ±0.2°C accuracy provides

a comprehensive and precise testing environment. Military equipment

often operates in a wide variety of temperature extremes, and this

accurate temperature control ensures that the test conditions

closely match the demands of Military Standard 810G, Method 509.5.

For example, electronic components in a missile guidance system

must function accurately in both the frigid cold of high-altitude

flight and the intense heat generated during launch and operation.

- Thermal Shock Cycle Parameters

- The chamber can be programmed to perform a customizable number of

thermal shock cycles, ranging from a few dozen to several thousand,

depending on the specific requirements of the military equipment

and its expected service life. The dwell time in each temperature

zone can be adjusted from milliseconds to hours, allowing for the

simulation of a vast array of mission profiles. For instance, a

reconnaissance drone may experience short, frequent thermal shock

cycles during its flight operations, while a stationary military

communication station may endure longer, less frequent cycles.

- Testing Volume and Payload Capacity

- The chamber offers a flexible testing volume, usually ranging from

3 m³ to 15 m³, to accommodate a wide variety of military equipment

and components, from small circuit boards to large weapon systems.

The payload capacity is designed to handle heavy and bulky items,

with a maximum capacity of up to several tons, ensuring that even

the most substantial military hardware can be effectively tested.

|