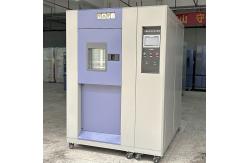

In the realm of machinery manufacturing, compliance with the

2006/42/EC test standard is of utmost importance. The Custom

Thermal Shock Chambers designed specifically for this standard

emerge as a crucial tool in ensuring the reliability and safety of

machinery components. This custom-built thermal shock chamber is dedicated to subjecting

machinery components to the rigorous testing requirements of the

2006/42/EC standard. It serves machinery manufacturers, research

institutions, and quality control laboratories. The primary

objective is to evaluate the ability of components such as gears,

bearings, shafts, and housings to withstand rapid and extreme

temperature changes. By simulating the thermal shock conditions

that these components may encounter during their operational

lifespan, manufacturers can identify potential weaknesses, optimize

material selection and manufacturing processes, and enhance the

overall durability and performance of their machinery. - Robust and Insulated Chamber Construction

- The chamber is constructed with heavy-duty, heat-resistant

materials that can endure the intense thermal stresses. The walls

are made of high-strength steel with advanced insulation layers to

minimize heat transfer between the different temperature zones. The

door is equipped with a reliable sealing mechanism and a viewing

window, allowing operators to monitor the testing process without

compromising the integrity of the chamber. The interior is designed

with a unique configuration to create distinct hot and cold zones,

ensuring rapid and uniform temperature transitions.

- Precision Temperature Control System

- Temperature Range and Transition: Capable of achieving a wide

temperature range, typically from -60°C to +180°C. The system can

rapidly switch between the hot and cold zones, with a transition

time as short as a few minutes. This is essential for replicating

the sudden temperature changes that machinery components may

experience, such as when a machine is started in a cold environment

and quickly reaches operating temperature or when it is exposed to

external heat sources during operation. The temperature control is

accurate to within ±0.5°C, ensuring reliable and repeatable test

results.

- Intuitive Control Panel and Data Acquisition Interface

- The control panel is user-friendly and enables operators to easily

set and adjust test parameters such as temperature levels, dwell

times in each zone, and the number of thermal shock cycles. It

provides real-time displays of the current temperature in both

zones, the status of the testing process, and any alarms or

warnings. The chamber is integrated with a comprehensive data

acquisition system that records all relevant test data. This

includes temperature histories, cycle times, and any observable

changes in the physical or mechanical properties of the components.

The data can be stored in a built-in memory or exported to external

storage devices for further analysis. The system can also generate

detailed test reports in various formats.

- Safety Features and Alarms

- Over-temperature and over-current protection are crucial safety

features, ensuring that the chamber and the test samples are not

damaged in case of a temperature control malfunction. Emergency

stop buttons are strategically placed for immediate shutdown if

required. Alarms are triggered for abnormal temperature

fluctuations, equipment failures, or any other safety-related

issues. The chamber is also equipped with proper ventilation and

exhaust systems to handle any potentially harmful gases or vapors

that may be generated during the testing process.

- Temperature Range and Accuracy

- The -60°C to +180°C temperature range with ±0.5°C accuracy provides

a comprehensive testing spectrum. Different machinery components

may have different temperature tolerances and material properties.

For example, metal alloys used in high-temperature applications

need to maintain their strength and integrity at elevated

temperatures, while polymers used in certain components may become

brittle at low temperatures. The accurate temperature control

ensures that the test conditions are precisely maintained, allowing

for a detailed assessment of component performance.

- Thermal Shock Cycle Parameters

- The chamber can be programmed to perform a specific number of

thermal shock cycles, typically ranging from 10 to 1000 or more,

depending on the requirements of the 2006/42/EC standard and the

nature of the components. The dwell time in each temperature zone

can also be adjusted, from a few minutes to several hours. This

flexibility allows manufacturers to simulate a wide variety of

real-world scenarios and evaluate the long-term durability of

components under different thermal shock conditions.

- Testing Volume and Payload Capacity

- The chamber offers a customizable testing volume, usually ranging

from 2 m³ to 10 m³, to accommodate a significant number of

machinery components. The payload capacity is designed to handle

heavy and bulky parts, with a maximum capacity of up to several

tons. This enables efficient testing of both individual components

and small assemblies.

- Data Sampling Frequency and Resolution

- The data acquisition system samples data at a frequency of up to

500 Hz. The temperature data has a resolution of 0.1°C. This

high-resolution and frequent sampling enable the detection of even

the slightest temperature changes and trends, providing valuable

insights into the behavior of the machinery components during

thermal shock testing.

- Accurate Simulation of 2006/42/EC Test Conditions

- The chamber replicates the exact thermal shock conditions specified

in the 2006/42/EC standard. This is crucial as machinery components

must meet these requirements to ensure their compliance and safety.

By subjecting the components to these precise simulations,

manufacturers can be confident that their products will perform as

expected in real-world applications.

|