In the realm of product testing and quality assurance, the ability

to subject materials and components to rapid and extreme

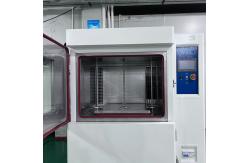

temperature changes is of utmost importance. The customized thermal

shock test chamber, with a temperature range spanning from -55℃ to

150℃, emerges as a powerful tool that enables manufacturers and

researchers to evaluate the durability and performance of a wide

array of products under the harshest thermal conditions. This highly specialized test chamber is designed to replicate the

rapid temperature fluctuations that products may encounter during

their operational lifetimes or in extreme environmental scenarios.

It caters to a diverse range of industries, including aerospace,

automotive, electronics, and military. The primary objective is to

identify potential weaknesses, such as material fatigue, cracking,

or delamination, that can occur due to sudden and severe

temperature differentials. By subjecting samples to thermal shock

cycles, manufacturers can optimize product designs, enhance

reliability, and ensure compliance with stringent industry

standards. - Robust and Insulated Chamber Structure

- The thermal shock test chamber is constructed with a heavy-duty

steel frame that provides exceptional rigidity and stability. The

frame is coated with a corrosion-resistant finish to prolong its

service life. The chamber is divided into two distinct

compartments, a hot zone and a cold zone, each with its own

independent temperature control system. The walls of the chambers

are made of high-quality insulation materials, which minimize heat

transfer between the zones and maintain precise temperature levels.

The insulation is carefully engineered to withstand the rigors of

continuous thermal cycling and prevent any external factors from

interfering with the internal test environment. The chamber is also

equipped with a hermetic door seal, ensuring a leak-free enclosure

and consistent test conditions.

- Precision Temperature Control System

- Each zone of the chamber features a highly accurate temperature

control system. The hot zone can maintain temperatures up to 150℃

with an accuracy of ±0.5℃, while the cold zone can reach as low as

-55℃ with the same level of precision. The systems utilize advanced

heating elements and refrigeration units, along with PID

controllers, to achieve and maintain the desired temperature

settings. Temperature sensors are strategically placed within the

chambers to provide real-time feedback, enabling the control

systems to make rapid and precise adjustments. The ability to

transition between extreme hot and cold temperatures quickly is a

key feature, with a typical temperature change rate of up to 20℃

per minute.

- Versatile Sample Handling Mechanism

- The chamber is equipped with a sophisticated sample handling

mechanism that allows for easy and efficient transfer of test

samples between the hot and cold zones. This can be achieved

through a pneumatic or mechanical transfer system, which ensures

rapid movement of samples without significant temperature

equilibration during the transfer process. The system is designed

to accommodate a variety of sample sizes and shapes, and can be

customized to meet specific testing requirements. Additionally, the

chamber can be fitted with sample holders and racks made of

non-corrosive and heat-resistant materials to ensure proper sample

positioning and support.

- Intuitive Control and Data Acquisition Interface

- The equipment is equipped with an intuitive control panel and a

comprehensive data acquisition system. The control panel allows

operators to easily set and adjust the temperature parameters, test

durations, and cycle repetitions. It provides real-time display of

the current temperature in each zone, as well as any alarms or

warnings. The data acquisition system records all relevant test

data, including temperature profiles, temperature change rates, and

any changes in the physical properties of the test samples. The

data can be stored in a built-in memory or exported to external

storage devices for further analysis. The system also has the

ability to generate detailed test reports in various formats, such

as PDF or Excel.

- Safety and Protection Mechanisms

- To ensure the safety of operators and the integrity of the testing

process, the chamber is equipped with a range of safety features.

It has emergency stop buttons strategically located for immediate

shutdown in case of any abnormal situation. The chamber is also

protected against over-temperature and over-current conditions,

with built-in safety circuits that automatically cut off power if

necessary. Additionally, the chamber is designed to prevent any

refrigerant leaks, and it has a ventilation system to ensure the

removal of any potentially harmful gases. The door of the chamber

is interlocked, preventing it from being opened during a test cycle

to avoid sudden temperature changes and potential hazards.

- Maximum Temperature Swing

- The chamber can achieve a maximum temperature swing of 205℃ (from

-55℃ to 150℃). This wide temperature range allows for the

simulation of the most extreme thermal conditions that products may

face. For example, in aerospace applications, components may

experience rapid temperature changes during flight, such as when

transitioning from the cold upper atmosphere to the hot engine

compartment. Testing within this temperature swing helps to

identify potential issues related to thermal expansion and

contraction, ensuring the reliability of critical aerospace

systems.

- Temperature Change Rate

- As mentioned, the temperature can change at a rate of up to 20℃ per

minute. This rapid rate of change is essential for accurately

simulating real-world thermal shock events. In the electronics

industry, for instance, components may be exposed to sudden

temperature changes when a device is powered on or off, or when it

is moved from a cold storage environment to a warm operating

environment. By testing at this rate, manufacturers can evaluate

the ability of electronic components, such as circuit boards and

semiconductors, to withstand thermal stress without failure.

- Testing Volume and Payload Capacity

- The chamber offers a customizable testing volume, with options

ranging from 1 m³ to 20 m³. The payload capacity can be adjusted

according to the size and weight of the test samples, with a

maximum capacity of up to 1000 kg. This flexibility allows for the

testing of a wide variety of products, from small electronic

modules to large industrial components. For example, in the

automotive industry, it can be used to test the durability of

engine parts, transmission components, or even entire vehicle

subsystems.

- Temperature Uniformity

- The chamber ensures excellent temperature uniformity within each

zone. The temperature variation within the hot zone and the cold

zone is typically within ±1℃. This level of uniformity is crucial

for obtaining accurate and reliable test results, as it ensures

that all parts of the test sample are exposed to the same

temperature conditions. In applications where precise temperature

control is essential, such as in the testing of sensitive

electronic components or high-precision optical devices, this

feature is of utmost importance.

- Dwell Time Accuracy

- The chamber can maintain the specified dwell times at different

temperature levels with an accuracy of ±1 minute. Dwell time is an

important parameter in thermal shock testing, as it determines the

length of time the product is exposed to a particular temperature.

Accurate control of dwell time ensures that the test is conducted

in accordance with the defined test plan and provides consistent

results. For example, in testing the reliability of a new material,

the dwell time at extreme temperatures can help to assess its

long-term stability and resistance to thermal degradation.

|