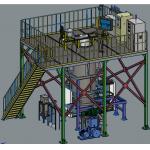

Superalloy Powders Plasma Rotating Electrode Process Equipment Fast Solidification

|

|

Plasma Rotate Electrode Process(PREP)

Overview Metal or alloy are made into consumable electrodes as feedstock. Its end face is heated by plasma torch and melt into molten liquid, then the molten is ejected by the centrifugal force of high-speed rotating electrode, crushed into small droplets and solidified into powders. Helium is the best choice as protective atmosphere because its thermal conductivity is highest and alsmost 10 times of Ar. By using helium, cooling speed can be increased and plasma torch performance can be improved.

Schematic Diagram

This equipment is used for producing superalloy powders of 50-500 micron which are applied as materials for high temperature rotating components of turbine disc of aero engine, compressor disc, etc and for energy conversion devices of aerospace craft, nuclear reactor, petrochemical equipment, and coal conversion etc.

Features

TC4 Powders SEM, PREP(left) and GA(right)

Specifications

|

| Product Tags: aluminum powder making machine gas atomization powder manufacturing equipment |

|

Spherical Shape Metal Powder Gas Atomization Equipment |

|

380V 50Hz Vacuum Melting Inert Gas Atomization Equipment |

|

Vacuum Gas Atomizing Equipment For Metal Powder |

|

Superalloy Powders Plasma Rotating Electrode Process Equipment Fast Solidification |

|

Electrode Induction Melting Gas Atomization Equipment With Low Consumption |

|

Inert Protective Gas Atomization Powder Manufacturing Equipment High Automation |