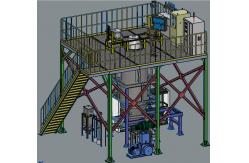

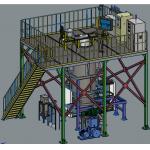

Electrode Induction Melting Gas Atomization Equipment With Low Consumption

|

|

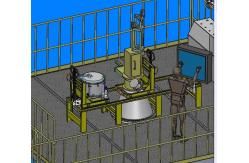

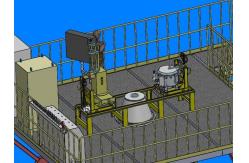

Electrode Induction Melting Gas Atomization (EIGA)

Overview Principle: Under vacuum or inert gas protection, the slowly rotating feedstock rod is heated by high frequency induction coil and melted inductively and continuously in the absence of crucible. Then the molten falls free, flows into atomization system and is crushed into a large number of small liquid droplets by high pressure inert gas from atomizer spray plate. Then small liquid droplets are solidified into spherical granular powders in flight. Feedstock doesn’t contact with crucible and fluid limiting diversion tube, so it doesn’t get pollution.

Features:

Specifications

|

| Product Tags: aluminum powder making machine gas atomization powder manufacturing equipment |

|

Spherical Shape Metal Powder Gas Atomization Equipment |

|

380V 50Hz Vacuum Melting Inert Gas Atomization Equipment |

|

Vacuum Gas Atomizing Equipment For Metal Powder |

|

Superalloy Powders Plasma Rotating Electrode Process Equipment Fast Solidification |

|

Electrode Induction Melting Gas Atomization Equipment With Low Consumption |

|

Inert Protective Gas Atomization Powder Manufacturing Equipment High Automation |