Spherical Metal Powder Atomization Equipment , Copper Powder Manufacturing Process

|

|

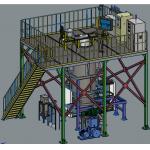

100 Kg (VIGA) Vacuum Gas Atomization Powder Manufacturing Equipment With Good Spherical

Overview

Working principle: 1.Metal or alloy materials are melted under inert gas protection or vacuum condition, and the molten metal is poured through insulation tundish system into a gas nozzle where the melt stream is disintegrated into droplets by high pressure inert gas stream. 2.The small droplets will be solidified into tiny spherical powders in flight in the atomization tower. Vacuum melting inert gas atomization powder manufacturing equipment is designed for producing metallic spherical powder by atomizing under certain conditions.

Features: 1. Combined with high vacuum technology, high temperature melting technology and high pressure gas atomization technology, vacuum melting inert gas atomization powder manufacturing equipment is especially suitable for the production of high quality powders and active metals/alloys. 2. The produced powders have the characteristics of high purity, low oxygen content, high yield of fine powders, good appearance, etc..

Optional functions:

|

| Product Tags: gas atomization powder manufacturing equipment gas atomization process |

|

Spherical Shape Metal Powder Gas Atomization Equipment |

|

380V 50Hz Vacuum Melting Inert Gas Atomization Equipment |

|

Vacuum Gas Atomizing Equipment For Metal Powder |

|

Superalloy Powders Plasma Rotating Electrode Process Equipment Fast Solidification |

|

Electrode Induction Melting Gas Atomization Equipment With Low Consumption |

|

Inert Protective Gas Atomization Powder Manufacturing Equipment High Automation |