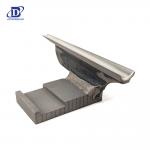

Product OverviewThe cigarette tongue, a core and crucial component in the cigarette machine's rolling

and forming system, acts like an unsung yet vital hero, playing an

irreplaceable role in the cigarette production process. It is

typically installed between the high-pressure thread catcher and

the cigarette gun of the cigarette machine, and its unique

structural design lays a solid foundation for the efficient and

stable operation of cigarette production. In terms of appearance,

the overall structure of the cigarette tongue is a gradually

shrinking semi-conical groove, which is no accident but has been

obtained through numerous practices and optimizations, perfectly

matching the needs of the cigarette production process. - Excellent Wear Resistance: Our cigarette tongues are carefully selected in terms of

materials, made of high-quality steel, and some models even use

high-tech materials such as wear-resistant ceramics or high

manganese wear-resistant steel. This ensures that the cigarette

tongue can maintain excellent wear resistance when facing

high-intensity and high-frequency friction, effectively extending

the product's service life. Taking a certain model of cigarette

tongue designed for high-intensity production environments as an

example, after a long period of actual production testing, its wear

resistance has been improved several times compared with ordinary

cigarette tongues, which greatly reduces the number of times the

equipment needs to be shut down for maintenance due to wear of the

cigarette tongue, significantly improves production efficiency, and

reduces the production cost of enterprises.

- Precise Dimensional Accuracy: The dimensional accuracy of the cigarette tongue has a crucial

impact on the stability of cigarette quality. We are well aware of

this, so in the production process, we have invested a lot of

manpower, material resources and advanced technical equipment to

strictly control the dimensional accuracy of the cigarette tongue.

By adopting high-precision processing technology and advanced

testing equipment, we ensure that the size of each cigarette tongue

can be accurate to the millimeter or even micrometer level,

achieving perfect adaptation with other components of the cigarette

machine. Whether it is for conventional cigarettes, or for the

production of special specification products such as slim

cigarettes and bead filter rods, which have gradually increasing

market demand in recent years, our cigarette tongues can rely on

their precise dimensional accuracy to provide a solid guarantee for

the stable quality of cigarettes.

- Optimized Structural Design: In order to better meet the needs of different cigarette

production processes, our cigarette tongues have unique ingenuity

in structural design. Some cigarette tongues adopt an innovative

split design, cleverly dividing the cigarette tongue into two

parts: the cigarette tongue fixing bracket and the pluggable arc

groove module. This design not only makes the replacement and

maintenance of parts more convenient and efficient, greatly

reducing maintenance costs, but also can flexibly choose modules of

different materials for matching according to the actual use

situation, further improving the performance of the cigarette

tongue. For example, in some production scenarios with extremely

high requirements for the wear resistance of the cigarette tongue,

pluggable arc groove modules with stronger wear resistance can be

selected, while in other scenarios, reasonable adjustments can be

made according to actual needs. In addition, some cigarette tongues

have been specially optimized in structure. Through the clever

setting of air inlets, air outlets and other structures, the

secondary wind blowing of the tobacco strand is realized, which

effectively breaks up the strand nodes, stretches the strand, slows

down the rebound, significantly increases the filling amount of the

strand in the filter rod forming process, reduces the retraction

rate of the filter rod after forming, and thus greatly improves the

quality of cigarette products.

|