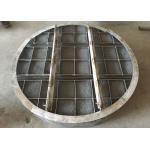

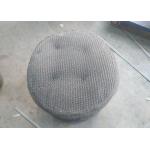

Din Stainless Steel Wire Mesh Pad

|

|

Din Stainless Steel Wire Mesh Pad Replacement 3 Phase Separator

Vapor-liquid separator

Only when there is air space inside the chamber, the vapor-liquid separator is effective. It can fail either when the mixed stream inlet is overwhelmed or the draining of collected liquid is slower than its growing. Considering this, the separator may be combined with some liquid level sensing accessories, such as a sight glass or float sensor. By doing this, both the supply and drain flow can be regulated to prevent the separator from being overloaded.

In refrigeration systems, it is common for the system to contain a mixture of liquid and gas, but for the mechanical gas compressor to be intolerant of liquid. Some compressor types such as the scroll compressor use a continuously shrinking compression volume. Once liquid completely fills this volume the pump may either stall or overload, or the pump chamber may be warped or otherwise damaged by the fluid that can not fit into a smaller space.

Demister pad vapor liquid separator in this case:

Industrial areas that need demister vapor-liquid separator:

Marine, desalination; Oil& gas; Petrochemical Chemical plant Pharmaceutical Sugar manufacturing Pollution control

Typical usages of wire mesh demister vapor-liquid separator:

Steam boiler Cooling tower Distillation column Absorption column Oil mist elimination Gas and air scrubber Vacuum and drying tower Effluent gas treatment in sulphuric acid factories |

||||||||||||||||||||||||||||||||||||

| Product Tags: vapour liquid separator vapor liquid separation |