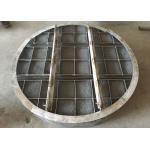

Alloy 20 Material Wire Mesh Mist Eliminator

|

|

Alloy 20 Material Wire Mesh Mist Eliminator And Other Options HL-130

The Cr content of alloy 20 (n08020) nickel base alloy is usually 19.0% - 21.0%, and the nickel content is 32.0% - 38.0%. Alloy 20 (incoloy20) is a nickel base alloy with molybdenum and copper, which has good hot and cold working properties. Alloy 20 (n08020) nickel base alloy is a corrosion-resistant alloy with many excellent properties. It has good resistance to oxidation and medium reduction corrosion, excellent resistance to stress corrosion cracking and good resistance to local corrosion. It has satisfactory corrosion-resistant characteristics in many chemical process media.

Other material of construction

Mesh and grids may be made from most metals and plastics i.e. SS304, 304L, 316, 316L, 321, 310S, 201, Duplex 2205, 316Ti, 904L, Monel, Nickel, Copper, P.T.F.E., H.D.P.E., P.P., co-knit of 316L + PTFE, alloy 20 + PTFE, 304+PTFE, 904L + PTFE, 304+glass fiber, 316L + glass fiber, 904L + glass fiber, 316L+PP etc. and other metals, alloys or plastic which can be drawn or extruded.

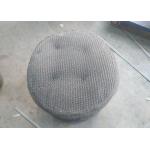

When properly designed demister pads can give efficiency up to 99.9% with minimal pressure drop. Normally demister pads can remove droplets down to 5 microns and lower with a free volume of up to 99% and a surface area of up to 1940 m2/m3. Due to high value of free volume the pressure drop across the demister pad is sufficiently low in most applications.

When wire mesh mist eliminator should be replaced?

Due to the fact that the mesh pad demister is normally installed in a major process line, it is almost impossible to replace them while the lines are in operation. Therefore, for economy purpose, it is important to have them replaced during annual or periodic shut-down period. For these reasons, the followings are presented for the user’s consideration. When the thickness has changed. When the tightness of each pad sections has changed. When the corrosion of the wire is severely noticed. When the entrained mist or dust gives pressure drop hazard. Others as having been experienced by maintenance engineers.

Hualai's advantages in wire mesh mist elliminator (vapor liquid separator):

Prevention of air pollution Reduce of costly liquid lose Reduce of product contamination Improvement in process efficiency Minimizing product losses in re-boilers & evaporators Preventing carbon & metal entrainment in down stream catalyst cracker. |

||||||||||||||||||||||||||||||

| Product Tags: vapour liquid separator vapor liquid separation |