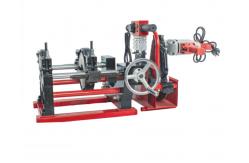

PE PVDF Pipe Hydraulic Hdpe Butt Fusion Welding Machine Hot Melt

|

|

PE PVDF Pipe Hydraulic Hot Melt Welding Machine Hdpe Butt Fusion Welding Machine Plastic Pipe Field Butt Welder PVDF PP Tube Welders Hydraulic Automatic HDPE 220V Plastic Butt Fusion Welding Machine For 63mm to 160mm

Plastic pipe welding machine Application The machine should be operated on a dry area. The protective measures should be adopted when it's used in rain or on wet ground. The machine is operated by 220v±10%, 50Hz, if extended wire should be used, it should have enough lead section according to its length. Milling cutter with limit switch can prevent the accidental activation.The raw material of the machine frame is aluminum alloy, 45°slant design, is better to operate.

Plastic pipe welding machine Technical Data

PreparationPreparation for welding HDPE Pipe manual Butt Fusion Welding

Machine 1. Before operation, all equipment parts shall be placed on

a stable and dry place. 2. Confirm that the power supply used meets

the requirements of the equipment, the equipment is in good

condition, and the electrical circuit is not damaged; the detection

indicator works normally, the milling cutter blade is sharp, and

the parts and operating tools are complete. 3. Replace the required

fixture according to the outer diameter of the welded pipe.

Other size in option We have size of 160mm, 200mm, 250mm, 315mm, 355mm,450mm,630mm,800mm, 1200mm,1600mm. Welding procedure

Advantage 1. Using Teflon coating material imported from Japan, after twice

coating and three processes.

1. High power milling cutter, mirror cutter disk, strong motor,

high concentricity, smooth milling.

HDPE melt-up time pressure reference list welding temperature: 210 degrees.

Note: if the environment temperature is less than 5℃ , heating time should be extended by 5% Learning of hot melt welder A hot melt welder, also known as a hot melt welding machine or hot air welder, is a tool used for joining thermoplastic materials together. It uses heat to soften the plastic surfaces and then applies pressure to fuse them, creating a strong bond.

Here's a basic overview of how a hot melt welder typically works: Heating Element: The hot melt welder features a heating element or heat gun that produces a stream of hot air or an electrically heated element. This heat source is used to heat the surfaces of the thermoplastic materials to their melting point. Preparation: Before welding, the surfaces to be joined are usually cleaned and prepared to ensure proper adhesion. This may involve removing any contaminants or roughening the surfaces to improve bonding. Heating and Melting: The hot air or heating element is directed onto the surfaces of the thermoplastic materials, softening them and bringing them to a molten state. The heat is applied evenly to both surfaces to ensure proper fusion. Pressure Application: Once the surfaces are sufficiently heated and melted, the hot melt welder applies pressure to bring the surfaces together. This pressure helps to ensure intimate contact between the molten plastic, allowing it to fuse and create a strong bond. Cooling and Solidification: After the pressure is applied, the hot air or heating element is removed, and the welded joint is allowed to cool and solidify. The cooling process allows the molten plastic to harden, forming a solid and durable weld. Hot melt welders are commonly used in various industries, including plastics fabrication, automotive repair, roofing, and flooring installation. They are especially effective for joining thermoplastic materials such as PVC, polypropylene, polyethylene, and ABS.

It's important to note that different types of hot melt welders may have varying features and capabilities. Some hot melt welders may also incorporate additional functions, such as temperature control, speed control, or different nozzle attachments, to accommodate different applications and materials. When using a hot melt welder, it is essential to follow the manufacturer's instructions and safety guidelines to ensure proper operation and minimize the risk of injury or damage.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Hydraulic Hot Melt Welding Machine 270 degree Hot Melt Welding Machine 270 degree hdpe butt welding machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20-315mm PP Electrofusion Welding Machine 350A With Electrofusion Welding Unit Scanner And Printer |

|

20-200mm Electro Fusion Pipe Welding Machine 200A With Electrofusion Welding Unit Scanner And Printer |

|

90-315mm High Pressure HDPE Fusion Welding Machine / Butt Welder For 315mm Pipe |

|

PE PVDF Pipe Hydraulic Hdpe Butt Fusion Welding Machine Hot Melt |

|

HDPE PVDF PP Tube 220V Plastic Butt Fusion Welding Machine For 63mm to 160mm |

|

PVDF And PP Pipe Jointing Hdpe Plastic Butt Fusion Welding Machine 2.3KW |