IML Dairy Packaging Food Label Defect Detection Equipment with CMOS Camera

|

|

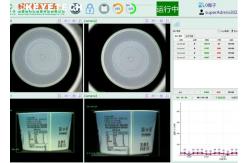

IML Dairy Packaging Food Label Defect Detection Equipment with CMOS Camera Food Label Defect Detection Equipment Food label defect detection equipment is mainly for the label detection on food packaging. The label contains important information of food, including barcode, production date, batch number, etc. Usually the shelf life of food is very short, if the label is missing, blurred, black spots , offset and other problems may affect the sales of food, causing loss of merchants and waste of products, so many food factories will do special testing for food labels.

ompany Profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries. The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Software Function Ø Enabling and disabling the system detection function Ø Detection index parameters and accuracy adjustment Ø Template sampling and saving, storage and retrieval of sample information Ø Camera screen calibration function Ø Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions Ø Manage permissions based on login account (example, disabling parameter adjustment for general operation users) Ø Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Equipment Overview:

Product superiority

|

||||||||||||||||||||

| Product Tags: Food Label Defect Detection Equipment Food Packaging Defect Detection Equipment | ||||||||||||||||||||

|

Single Camera In-Mold Labeling Product Vision Inspection System |

|

User Friendly IML Take In Take Out with AI Vision Inspection System |

|

Plastic Ice Cream Cup Surface Defects Vision Inspection Machine |

|

Paper Plastic Cup Quality Checking Machine with CMOS Camera Inspection System |

|

AI Based Camera Inspection Machine Before IML Cup Loading and Stacking |

|

IML Dairy Packaging Food Label Defect Detection Equipment with CMOS Camera |