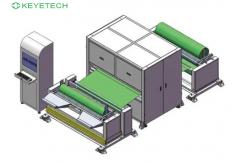

Paper Plastic Cup Quality Checking Machine with CMOS Camera Inspection System

|

|

Paper Plastic Cup Quality Checking Machine with CMOS Camera Inspection System Company Profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries. The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Overview The design scheme uses high-pixel industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of products. The inspection speed is 60-150 pcs/min, and the equipment can operate 24 hours a day. Products can be automatically rejected online.

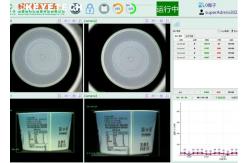

Software Function

Operation Parameters

Cooperation Partners KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry. ** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

Delivery Time The production cycle of the whole machine is expected to take 60 days. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site. |

||||||||||||||||

| Product Tags: 200m/min Textile Inspection Equipment PVC Tarpaulin Canvas Inspection Equipment |

|

Single Camera In-Mold Labeling Product Vision Inspection System |

|

User Friendly IML Take In Take Out with AI Vision Inspection System |

|

Plastic Ice Cream Cup Surface Defects Vision Inspection Machine |

|

Paper Plastic Cup Quality Checking Machine with CMOS Camera Inspection System |

|

AI Based Camera Inspection Machine Before IML Cup Loading and Stacking |

|

IML Dairy Packaging Food Label Defect Detection Equipment with CMOS Camera |