Computer To Screen CTS Imaging & Exposure System Machine Textile Clothing Printing

|

|

Computer to screen (CTS) imaging & exposure system Machine Textile Clothing Printing

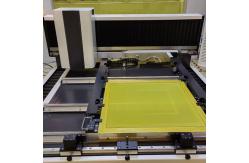

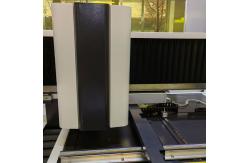

CTS100 Computer to screen (CTS) machine is mainly for screen making in the textile printing industry. Its precision is 1270 or 2540 dpi, and the maximum screen size is 900x1000 mm. The focusing mode is dynamic focusing, and the production capacity can reach 120 S/m2 (according to the characteristics of photoresist). Because of its unique high performance and equipment flexibility, CTS100 is extremely suitable for screen making in the printing industry, and has become the preferred plate making product for many textile printing enterprises. Max Screen Size 900*1000 Computer To Screen machine

Advantages

The maximum screen frame size can reach 900x1000.

High Precision:

Low Cost: |

||||||||||||||||||||||||||||||||||||

| Product Tags: CTS Imaging Exposure System Textile CTS Imaging Exposure System Clothing Printing CTS System |

|

1270dpi 133LPI CTS Computer To Screen Exposing Machine C High-Precision Vertical Computer-to-Screen Exposure Machine for Infinite Creative Possibilities |

|

1270dpi 133LPI CTS Computer To Screen Exposing Machine CTS 2200*3200mm screen |

|

133LPI CTS Computer To Screen Exposing Machine Resolution 12700dpi 2200*3200mm |

|

Computer To Screen CTS Machine For Textile Clothing Printing DMD Tech No Filme |

|

Computer To Screen CTS Imaging & Exposure System Machine Textile Clothing Printing |

|

CTS100 CTS Computer To Screen UV Laser 400nm-410nm Textile Glass Printing |