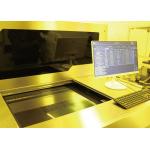

260mmx810mm LDI System Roll To Roll PCB HDI FPC 380V Three Phase

|

|

laser direct imaging (LDI) system solutions LDI Roll to Roll PCB

Advantages of LDI over Photo Processing

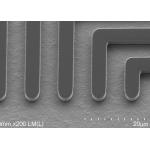

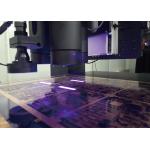

Traditional photo processes requires multiple steps to create the phototool used to generate the image on the PCB. This has generated a number or challenges for PCB fabricators over the years. LDI provides a number of advantages: · Quality – photo film issues in the past have resulted in imperfect images due to inherent susceptibility to fluctuations in temperature or humidity. Laser images result in much more precise and consistent images, and eliminate any film-related defects. · Laser imaging provides precise positioning and improved resolution. Image lines, spaces, and alignment are more accurate. · Photo methodology requires temperature and humidity controlled environments to provide the most accurate transfer of images to boards. LDI reduces the impact of environment on the resulting images, and removes the impact of light refraction inherent with photo processing techniques. LDI fabrication offers specific advantages where short runs or quick turn-around are required, making creation of artwork and setup of phototool methods impractical. LDI is also an important factor when close tolerances and tight registration are involved. Today’s customer demands for smaller, lighter, high-density PCBs are quickly edging out photo technology as a practical tool in generating PCB images.

|

||||||||||||||||||||||||||||

| Product Tags: 260mm LDI System 380V LDI System Three Phase ldi machine |

|

HDI FPC PCB LDI Laser Direct Imaging 380V Three Phase |

|

15um LDI System Roll To Roll PCB Laser Direct Imaging System 24um 12um |

|

260mmx810mm LDI System Roll To Roll PCB HDI FPC 380V Three Phase |

|

12um 24um Laser Direct Imaging Equipment PCB ISO 9001 CE |

|

LD Laser LDI System 400nm To 410nm 15um |

|

LDI Roll To Roll Direct Imaging PCB 380V Three Phase |