laser direct imaging (LDI) system solutions LDI Roll to Roll PCB

PCB laser direct imaging (LDI)

A laser direct imager (LDI) is an advanced exposure unit that replaces the traditional flood exposure units used in the past. Patterns are

plotted on a digital file, instead of the phototools of old, and

those digital files are uploaded into the LDI, which will

selectively image it on your substrate.

How does laser direct imaging ( LDI ) work?

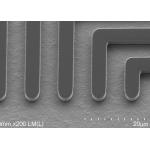

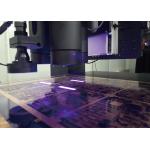

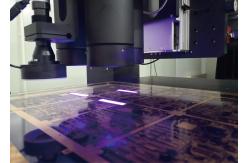

Laser direct imaging needs a PCB with the photo-sensitive surface

that is positioned under a computer controlled laser. And then the

computer is creating the image on the board with the light of

laser. A computer scans the board surface into a raster image,

matching the raster image to a pre-loaded CAD or CAM design file

that includes the specifications for the necessary image intended

for the board, the laser is used for directly creating the image on

the board.

| Specification/model | RTR315 |

| Application | PCB,HDI,FPC (inner layer,outer layer,anti-welding) |

| Resolution (mass production) | 15um |

| Capacity | 12S@18"*24" |

| Exposure Size | 260*800mm |

| Panel thickness | 0.05mm-3.5mm |

| Alignment Mode | UV-Mark |

| Alignment capability | Outer layer±12um;Inner laye±24um |

| Line width tolerance | ±10% |

| Deviation increase and decrease mode | Fixed increase and contraction, automatic increase and contraction,

interval increase and contraction, partition alignment |

| Laser type | LD Laser,405±5nm |

| File format | Gerber 274X;ODB++ |

| Power | 380V three-phase alternating current, 6.4kW,50HZ, voltage

fluctuation range + 7% ~-10% |

| Condition | Yellow light room; Temperature 22°C ± 1°C; Humidity 50% ± 5%;

Cleanliness level 10000 and above;

Vibration requirements to avoid violent vibration near the

equipment

|

About us

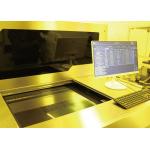

We are an innovative supplier of various PCB laser direct imaging

(LDI) system solutions. Our system product portfolio ranges from

LDI system configurations for high-mix and emerging PCB niche

applications to fully automated LDI system solutions for mass

production environments.