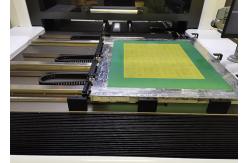

900x1000mm Computer To Screen Exposing Machine

|

|

CTS is a computer-to-screen (CTS) imaging and exposure system (Chinese, Japanese, Korean, EU patent). Some rayon screens are exposed and imaged. It is also suitable for some graphics applications. The exposure resolution of CTS on the screen (1270dpi) or 2540dpi, screen 133 lines. The efficiency of plate making is improved, It only takes 3 minutes to expose a 1 square meter screen. Accurate exposure alignment saves printing preparation time and reduces labor low cost. Because no film is required, it prevents the film from wearing and shrinking instability and causing quality problems. At the same time, the price of the film is higher, which saves a lot of cost. CTS laser direct plate making shortens the three steps of the traditional work exposure process into one step of the CTS work process to achieve the purpose of rapid plate making.

|

||||||||||||||||||||||||||||||||||||

| Product Tags: 1000mm Computer To Screen Exposing Machine 900mm Computer To Screen Exposing Machine Textile uv exposure machine |

|

1270dpi 133LPI CTS Computer To Screen Exposing Machine C High-Precision Vertical Computer-to-Screen Exposure Machine for Infinite Creative Possibilities |

|

1270dpi 133LPI CTS Computer To Screen Exposing Machine CTS 2200*3200mm screen |

|

133LPI CTS Computer To Screen Exposing Machine Resolution 12700dpi 2200*3200mm |

|

Computer To Screen CTS Machine For Textile Clothing Printing DMD Tech No Filme |

|

Computer To Screen CTS Imaging & Exposure System Machine Textile Clothing Printing |

|

CTS100 CTS Computer To Screen UV Laser 400nm-410nm Textile Glass Printing |