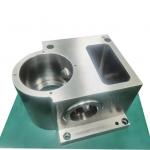

Hardened Metals Precision Cnc Machining Part Oem Customized Sizes Acceptable

|

|

Every piece undergoes rigorous quality checks, ensuring it not only meets but exceeds expectations. Our commitment to excellence is reflected in the reliability and longevity of the machined parts we deliver.

Material Excellence: 316 stainless steel, known for its corrosion resistance and durability, is meticulously machined to meet the demands of diverse industries. Its exceptional performance in challenging environments makes it a preferred choice for critical applications.

Custom Solutions: Understanding the importance of tailored solutions, our custom precision CNC machining 316 stainless steel service is committed to providing components that align perfectly with your OEM requirements. From intricate designs to specific tolerances, we ensure a seamless fit. 1. Corrosion Resistance: A Shield Against Deterioration

316L stainless steel boasts exceptional corrosion resistance, particularly in harsh environments. With a corrosion rate lower than conventional stainless steels, it remains an ideal choice for applications exposed to corrosive elements.

2. Chemical Composition: The Foundation of Excellence

Comprising iron, chromium, nickel, and molybdenum, 316L stainless steel's balanced chemical composition contributes to its corrosion resistance and durability. The alloy's low carbon content enhances its weldability and minimizes susceptibility to sensitization. 3. Temperature Resistance: Thriving in Extreme Conditions

With a melting point exceeding 2,500°F (1,371°C), 316L stainless steel maintains its structural integrity at elevated temperatures. This attribute is crucial for applications involving exposure to high heat, such as in industrial processes.

4. Tensile Strength: Robust Mechanical Performance

The tensile strength of 316L stainless steel ranges between 480 to 580 MPa, emphasizing its robust mechanical properties. This makes it suitable for applications requiring high strength and durability, such as in the aerospace and marine industries. Considerations:1. Cost: A Premium Material

While offering superior corrosion resistance, the cost of 316L stainless steel may be higher than that of standard stainless steels, impacting the overall project budget.

2. Machinability: Moderate Machining Challenges

The machinability of 316L stainless steel presents moderate challenges, and specialized tooling may be required for precision machining. FAQ: Q1:Where can I get product&price information? A1:Send us e-mail , we will contact you as we receive your mail. Q2: How soon can I get samples? A2: Depending on your specific project, it usually takes 3 to 5

days. Q3:How to enjoy the OEM services? A3:Usually, base on your design drawings or original samples, we

give some technical proposals and a quotation to you, after your agreement, we produce

for you. |

||||||||||||||||||||||||||||||||||

| Product Tags: Precision CNC Machining Parts OEM CNC Machining Parts Hardened Metals Precision Cnc Machining Part |

|

CNC Milling Services OEM 5-axis CNC Machining Parts With Deburring Process |

|

Polycarbonate CNC Milling with High Precision Tolerance of 0.01-0.005mm Sample Fee Required |

|

OEM CNC Milling Parts Customized Color CNC Machining Precision Metal Parts |

|

Hardened Metals Precision Cnc Machining Part Oem Customized Sizes Acceptable |

|

Precision CNC Machining Service Component Metal Machining Parts Aluminium CNC Machining Steel Rod |

|

CNC Machining Parts Of China Foundry Oem Custom CNC Machining Milling Aluminum CNC |