Product description

Product Name:

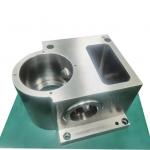

High difficulty CNC machining involves the production of intricate

components with complex geometries and tight tolerances, utilizing

advanced techniques and equipment. This type of machining requires

expert knowledge, meticulous planning, and precise execution.

Examples of high difficulty CNC machining include manufacturing

intricate aerospace components with intricate shapes and precise

dimensions, fabricating medical implants with complex contours and

tight tolerances, and creating precision gears with intricate tooth

profiles and high surface finish requirements. The challenges

inherent in high difficulty CNC machining necessitate skilled

operators, sophisticated CAD/CAM software, and state-of-the-art CNC

machines to achieve the desired results.

1. Multi-axis machining: High difficulty machining often involves

the use of advanced multi-axis CNC machines, such as 5-axis or even

9-axis machines. These machines can simultaneously move the cutting

tool along multiple axes, allowing for the production of complex

curved surfaces, undercuts, and intricate geometries that would be

difficult to achieve with traditional machining methods.CNC 4 Axis

5 Axis

2. Micro-machining: Micro-machining involves the production of

extremely small parts and features with dimensions in the

micrometer range. This requires highly precise machines, extremely

small cutting tools, and meticulous control of cutting parameters

to achieve the desired accuracy.Sheet Metal

3. Hard material machining: High difficulty machining may involve

working with hard materials, such as hardened steel, titanium, or

ceramics. These materials are difficult to cut due to their high

hardness and require special cutting tools, coatings, and machining

techniques to achieve the desired shapes and tolerances.

4. Thin-wall machining: Machining thin-walled parts requires

careful consideration to avoid distortion or damage during the

machining process. Special tooling, fixturing, and machining

strategies, such as vibration damping, are employed to ensure the

stability and integrity of the thin-walled workpiece.

5. Complex geometries and features: High difficulty CNC machining

often involves producing parts with intricate shapes, complex

contours, undercuts, or compound angles. This may require advanced

CAD/CAM software, skilled programmers, and specialized machining

strategies to accurately replicate the desired design.

High difficulty CNC machining requires a combination of advanced

machinery, skilled operators, precise programming, and meticulous

quality control to achieve the desired results. It is often

employed in industries such as aerospace, medical, complex tooling,

prototyping, and high-performance automotive components.

Advantages:

1) Provide non-standard/standard /OEM/ custom services CNC Lathe

2) High precision, tolerance up to 0.005mm

3) Short delivery cycle (5-7 days for samples, 12-15 days for mass

production)CNC 4 Axis 5 Axis

Shenzhen Hongsinn Precision Co., Ltd is a company that specializes

in the production of OEM mechanical parts, employing over 30

experienced technicians in casting, forging, and other

manufacturing processes. With a range of advanced equipment

including CNC machining centers, turning machines, milling

machines, and grinding machines, the company is capable of meeting

the diverse needs of industries such as automotive, medical, food,

new energy, communication, industrial equipment, aerospace, and

fixtures. Furthermore, Shenzhen Hongsinn Precision Co., Ltd prides

itself on its ability to provide high-quality products with quick

turnaround times, catering to both small and large-scale orders.

The company's management policy revolves around the principles of

quality, reputation, and customer satisfaction, while their working

concept emphasizes integrity, efficiency, professionalism, and

quality.