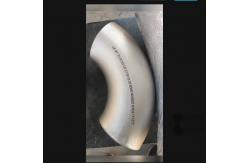

LR 90° Elbow B366 N08825 B16.9 Pipe Fittings Incoloy 825 Elbow

This LR 90° elbow is made from Incoloy 825 alloy to ASME B366 and

B16.9 standards and is suitable for piping systems in a variety of

industrial applications.

LR 90° Elbow:

LR: stands for Long Radius elbow, the bending radius is 1.5 times the

pipe diameter.

90°: stands for elbow with an angle of 90 degrees, commonly used to

change the direction of the pipe.

B366 N08825:

ASME B366: American Society of Mechanical Engineers standard covering alloy

seamless and welded pipe fittings.

N08825: Material grade, indicating that the elbow is made of Incoloy 825

alloy. Incoloy 825 is a nickel-iron-chromium alloy with excellent

corrosion resistance and high temperature performance.

B16.9:

ASME B16.9: American Society of Mechanical Engineers standard covering

factory-made steel seamless and welded fittings such as elbows,

tees, etc.

Application:

This elbow is commonly used in industries such as petroleum,

chemical, and power, especially in environments that require high

corrosion resistance and high temperature performance.

| Chemical Composition(%) | | | Ni | C | Fe | Mn | Cr | S | Mo | | 38.0-46.0 | 0.05max | 22.0min | 1.0max | 19.5-23.5 | 0.03max | 2.5-3.5 | | Si | Cu | Al | Ti |

|

|

| | 0.5max | 1.5-3.0 | 0.2max | 0.6-1.2 |

|

|

|

| Physical Constants | | Density | Melting Range | Specific Heat | Curie Temperature | | 0.294lb/in3 | 8.14Mg/m3 | 2500-2550°F | 1370-1400°C | 0.105Btu/lb•°F | 0.44J/kg•°C | <-320°F | <-196°C |

| Thermal Properties | | Temperature | Coefficient of Expansiona | Thermal Conductivity | Electrical Resistivity | | °F | 10-6in/in•°F | Btu-in/ft2•h•°F | ohm•circ mil/ft | | -250 | - | 55 | - | | -200 | - | 59 | - | | -100 | - | 66 | - | | 0 | - | 72.6 | - | | 78 | - | 76.8 | 678 | | 100 | - | 78.4 | 680 | | 200 | 7.8 | 85 | 687 | | 400 | 8.3 | 97.5 | 710 | | 600 | 8.5 | 109.7 | 728 | | 800 | 8.7 | 119.7 | 751 | | 1000 | 8.8 | 130.9 | 761 | | 1200 | 9.1 | 141.8 | 762 | | 1400 | 9.5 | 154.9 | 765 | | 1600 | 9.7 | 171.8 | 775 | | 1800 | - | 192.0 | 782 | | 2000 | - | - | 793 | | °C | µm/m•°C | W/m•°C | µΩ•m | | -150 | - | 7.9 | - | | -100 | - | 8.9 | - | | 0 | - | 10.7 | - | | 25 | - | 11.1 | 1.13 | | 100 | 14.1 | 12.3 | 1.14 | | 200 | 14.8 | 13.8 | 1.18 | | 300 | 15.3 | 15.4 | 1.21 | | 400 | 15.6 | 16.9 | 1.24 | | 500 | 15.8 | 18.2 | 1.26 | | 600 | 16.0 | 19.6 | 1.27 | | 700 | 16.7 | 21.2 | 1.27 | | 800 | 17.3 | 23.1 | 1.28 | | 900 | - | 25.5 | 1.29 | | 1000 | - | - | 1.30 |

DINGSCOHunan Dinghan New Material Technology Co., Ltd. (DINGSCO) specialized in Nickel Based Corrosion Resistant and High

Temperature alloys products which used in the world’s most technically demanding industries and applications.We are

dedicated to providing our customers with best quality products,

fastest possible deliveries, most competitive prices of Nickel

Based Corrosion Resistant and High Temperature alloys in bars, rods, forged flanges, valve parts (Ball, Stem, Seat Ring, etc), forged shapes (shafts, discs, blocks, hubs, rings, cylinders and other custom shapes) according to ASTM, ASME, API, AMS, NACE and other industry standards.

PROFESSIONAL NICKEL ALLOY MANUFACTURER - Monel, Incoloy, Inconel, Hastelloy

- VIM, ESR, Forging, Heat treatment, Machining

- Round Bar, Ball, Stem, Ring, Flange, etc

- ISO9001, API-6A, API-20B, PED, NORSOK

QUALITY ASSURANCE - Our in house QC Team, periodicly calibrated equipment and

measurement tools together with the test reports from state own

third party laboratory. that only Best Quality of our products can

be delivered to you.

- We provide EN 10204 Type 3.1 Certificates, Test / Examination

Reports of every order, we also welcome Any Third Party Laboratory

such as BV, SGS and others come to our factory for inspections.

CUSTOMIZED PRODUCTS:

APPLICATION: |