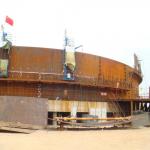

Advanced Large Storage Tank Horizontal Welding Machine

Precision Engineering for Industrial ExcellenceWINCOO ENGINEERING CO., LTD. specializes in delivering cutting-edge

welding solutions, including the MSHW-I Dual-Drive Automatic Submerged Arc Horizontal Welding

Machine, designed for high-efficiency welding of large storage tanks. This

state-of-the-art equipment combines robust performance with

intelligent automation, making it ideal for industrial applications

requiring precision and durability. Key FeaturesDual-Drive Flexibility: Supports both "top-to-bottom" and "bottom-to-top" welding modes,

ensuring seamless operation for vertical or horizontal circular

seams on tanks with diameters exceeding 4.5 meters. High-Performance Parameters: Welding Current: 300–500A (adjustable) Wire Diameter: Ø2.4–5.6mm Welding Speed: 350–750mm/min Applicable Thickness: 8–45mm steel plates.

Lincoln Welding System Integration: Equipped with a Lincoln NA3 welding head, DC600 power supply, and

advanced control systems for stable arc performance and consistent

weld quality. Automated Efficiency: Features a flux recovery system, laser-guided alignment, and

cross-slide adjustment mechanisms to minimize manual intervention

and optimize workflow. Safety & Compliance: Complies with strict operational standards, including pre-use

checks for electrical safety, anti-leakage mechanisms, and

environmental controls (e.g., ventilation, fire hazard prevention).

Technical Specifications Power Supply: 3-phase 380V ±10%, 50Hz Structure: Steel frame with (quenched steel) drive wheels, adjustable height

(2.0–3.2m shell width) Accessories: 80m welding cables, dedicated lighting, operator console, and

toolkits.

Applications

Ideal for petroleum, chemical, and energy industries requiring

large-scale storage tank fabrication. Its submerged arc welding

technology ensures airtight, high-strength joints while minimizing

spatter and oxidation. Why Choose Us?

WINCOO prioritizes innovation and reliability. Our welding machines

are engineered for longevity, backed by rigorous testing and

adherence to global safety protocols. With 24/7 technical support

and customizable solutions, we empower industries to achieve

unmatched productivity. |