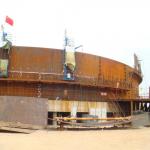

The MSHW-I Series represents the next generation of horizontal tank

welding machines, featuring integrated high-precision wire

oscillation for superior weld bead control and quality. Designed

for critical applications demanding flawless X-ray quality welds or

welding of thicker materials requiring wide beads, this system

offers unparalleled control over the welding arc. Its advanced

control system allows fine-tuning of oscillation parameters for

optimal fusion and penetration profiles. Key Specifications: Welding Process | Primarily Submerged Arc Welding (SAW), optimized for oscillation | Tank Diameter Range | 8 meters (26 ft) to 60 meters (197 ft)+ | Travel Speed | 100 - 600 mm/min (4 - 24 in/min), precise control | Drive System | High-torque servo-driven crawlers with strong magnetic adhesion

(e.g., 15,000 N / 3370 lbf) | Oscillation System | Programmable digital servo oscillation | Welding Head Adjustment | Motorized vertical & horizontal fine adjustment via remote

control | Control System | Advanced touchscreen HMI with data logging. Pre-programmed weld

procedures. Full remote operation capability | Power | 480V 3-phase | Compatibility | Interfaces with high-performance SAW power sources and heavy-duty

wire feeders |

Key Features: Precision Wire Oscillation: Enables wider beads, excellent sidewall fusion, uniform

penetration, and smooth bead contour – essential for high-quality,

defect-free welds (X-ray quality). Optimized for Thick Plate: Ideal for welding shell sections exceeding 25mm (1")

thickness in a single pass or fewer passes. Superior Process Control: Digital control over all parameters (travel speed,

oscillation width/freq/dwell, voltage, wire feed) ensures

repeatability. Reduced Welding Time: Wider beads reduce the number of passes required for thick

sections. Improved Weld Properties: Better heat distribution and fusion profile enhance

mechanical properties and reduce distortion. Enhanced Operator Interface: Intuitive touchscreen and remote control simplify operation

and monitoring from a safe distance. Data Logging: Records weld parameters for quality assurance and

traceability. Robust Magnetic Adhesion: Ensures reliable operation on vertical surfaces, even with

vibration.

Application Scenarios: Fabrication of high-integrity storage tanks for LNG, LPG, cryogenic services, or highly toxic chemicals requiring stringent weld quality standards (e.g., ASME Sect

VIII Div 1/2, API 620 Appendix Q/R). Welding of thick-walled pressure vessels and reactors in the oil & gas and petrochemical industries. Construction of nuclear containment vessels or penstocks demanding ultra-high weld integrity. Critical infrastructure tanks where weld reliability is paramount (e.g., strategic fuel

reserves). Applications requiring minimal post-weld grinding due to superior bead appearance.

|