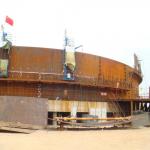

Precision And Automatic Girth Welder for LNG Tank

|

Large tank automatic girth welding machine is a high degree of automation, is a fully automatic large tank seam welding machine, its good welding quality, high production efficiency, welding position, obvious cost advantages, can be in a certain range, suitable for automatic welding of different volumes of tanks, the integrated structure of the machine makes the equipment more compact and beautiful.

The main process is: submerged arc welding, so it is also called submerged arc horizontal welding machine.Submerged arc welding is a welding method in which the arc formed between the wire and the weldment is used as the heat source, and the granular flux and slag covered around the arc are used as the protection medium. The submerged arc welding flux and the molten slag formed after melting play a role in isolating the air, preventing the weld metal from atmospheric pollution, and improving the performance of the weld. Horizontal submerged arc welding is a special form of automatic submerged arc welding, which is used to weld horizontal horizontal straight weld and horizontal girth weld. It can obtain transverse weld forming by using small welding power supply, arc voltage and high welding speed. This machine adopts flat characteristic welding power supply, equal speed wire feeding mode, reverse connection. The welding principle is the same as common submerged arc welding, the main difference is to solve the problem of molten metal and flux flow. Technical parameter of double side tank welding machine

Construction site picturesThe large tank submerged arc automatic girth welding machine is composed of the United States Lincoln welding power supply, welding car, the United States Lincoln wire feeder and control system, flux recovery system welding equipment, power supply, electric flux lifting crane, auxiliary power system and cable, operating platform/seat. Arrangement of automatic welderThe automatic submerged arc girth seam welding machine can be used together with several sets, and it is evenly distributed along the tank wall when it is arranged. The welding process of same direction, same speed, welding the outer wall first and then the inner wall is used for welding. Welding Procedures and Precautions1) Set the arc point of welding, let the welding wire gently contact the steel plate, and use contact arc. 2) Adjust the welding position of the operation lane, when driving in reverse, it is necessary to cross the welding arc point, and then turn forward to eliminate the mechanical gap and avoid welding bumps when arcing, and the arc point is at the back of the arc pit to avoid welding bumps or lack of meat. 3) Select the "welding" position of the driving switch; Select welding current, welding voltage, welding speed; Select the driving direction button and press "Go Left" or "Go Right". 4) Put the flux, cover the welding area, open the flux switch, and the recycler works. 5) Press "Welding" button to start arc welding. Adjust the welding current and welding voltage knob to the required value.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: LNG Tank Girth Welder Automatic Girth Welder Precision Girth Welder |

|

Automatic Tank Horizontal Seam Welding Machine with LINCOLN Power Supply |

|

Standard Heavy-Duty Horizontal Tank Welding Machine |

|

Large Oil Tank Construction Horizontal Seam Welding Machine with LINCOLN Power Source |

|

High Precision Tank Girth Welding Machine SAW Water Cooling Automatic Tank Girth Welding Machine |

|

Carbon Steel Large Automatic Girth Welding Machine For Intermediate Frequency Range |

|

Large Oil Tank Stainless Steel Automatic Tank Welding Equipment Inverter Electric Current |