Customized Bearing Roller Eddy Current Instruments For Non Destructive Testing ETP-2

|

Product Description:This system is specialized in serving bearing production factory about bearing roller flaw automatic testing ,it can also used to test magnetic or nonmagnetic in same dimension,this system can work in both online and offline,the detection sensitivity is high ,the level of automation is great,very easy to operate.equipped with automatic alarm and automatic sorting is the necessary nondestructive testing equipment in bearing production factory. This system adopts high stability eddy current flaw detector ,fixed balanced probes.workpiece automatic spiral forward,it can do nondestructive test on workpiece surface . This method is not adopt any coupling agent ,the probe and workpiece is going to test without touching. Hence it will never pollute and damage the surface of workpiece .the eddy current flaw detection produces high frequency can sense eddy current by testing probe on workpiece surface,the eddy current produces high frequency magnetic field in turn affect probe impedance. Once the workpiece surface find flaw, and destroy original eddy current field,it will cause the changes of probe impedance,instrument measuring the change of probe impedance so as to realize flaw testing automatically. The instrument is set with power regulation.sensitivity regulation and phase position regulation as well as impedance balance regulation rotary knob,so it can be adapt to every kind of dimension.the instrument also has fluorescent oscilloscope screen to display waveform and flaw echo,acoustic alarm can realize automatic alarm and monitor on excessive defects.Mechanical part uses vibrating disk feed mechanism,make sure workpiece enters into inspecting area automatically. Features:1. The equipment is small and compact so it can work on workbench 2. It adopts balanced spot probe with high testing sensitivity 3. Adopting vibrating disk type feed mechanism,non-contact test,strobe sorting with high degree of automation 4. It adopts fluorescent wave tube and high degree luminous tube ,testing condition can be seen directly Technical Parameters:

Support and Services:Technical Support and Service for ETP-2 Automatic Flaw Detector We provide technical support and service to ensure our customers are satisfied with their Portable Eddy Current Flaw Detector. We offer both on-site and online support for all of our products. On-site Support Our on-site support team is available to help with any installation, troubleshooting, or maintenance related issues you may have with your Portable Eddy Current Flaw Detector. Our technicians can come to your location and help with any questions or problems you may have. Online Support Our online support team is available 24/7 to help with any questions or issues you may have with your Portable Eddy Current Flaw Detector. We have a live chat feature on our website, as well as an online ticket system for more in-depth issues. Our team is always available to help. FAQ:Q1: What is the brand name of this product? A1: The brand name of this product is Desisen. Q2: What is the model number of this product? A2: The model number of this product is ETP-2 Automatic. Q3: Where is this product made? A3: This product is made in China. Q4: Does this product have any certification? A4: Yes, this product has ISO9001 certification. Q5: What's the minimum order quantity? A5: The minimum order quantity is 1. |

||||||||||||||

| Product Tags: Customized Bearing Roller eddy current instruments customized eddy current flaw detector Non Destructive eddy current flaw detector |

|

Intelligent Digital Eddy Current Flaw Detector A Relatively Independent Test Channel |

|

High Resolution LCD Eddy Current Flaw Detector Square Oval Flat Shaped Matials |

|

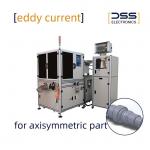

Eight Channels Microcomputer Controlled Eddy Current Flaw Detector Axisymmetric Part |

|

Automatic Bearing Roller Eddy Current Flaw Detector Large-scale Integrated Circuit |

|

Hardness Sorting Flaw Detection Synchronized Eddy Current Testing Machine Two Lines 4 Channels STY-2 |

|

Semi-automatic Analog Electronic Technology Digital Eddy Current Detector Cylinder Liner |