High Speed Rotating Scanner And Probe Portable Eddy Current Flaw Detector

|

|

Eddy current testing (ECT) is a technique used for contactless inspection of metal parts. Under the excitation of alternating current, the probe induces eddy currents in the part under test. Any discontinuities or changes in material properties that cause eddy currents to change are detected by the probe and treated as potential defects. Over the years, there have been continuous advances in probe technology and data processing, and eddy current technology is now recognized as a fast, simple, and accurate technique. This is why eddy current technology is widely used in industrial sectors such as aviation, automotive, petrochemical, and power production to detect surface or near-surface defects in materials such as aluminum, stainless steel, copper, titanium, brass, inconel, and even carbon steel. |

| Product Tags: High Speed Eddy Current Flaw Detector Probe Eddy Current Flaw Detector Portable Eddy Current Flaw Detector |

|

Intelligent Digital Eddy Current Flaw Detector A Relatively Independent Test Channel |

|

High Resolution LCD Eddy Current Flaw Detector Square Oval Flat Shaped Matials |

|

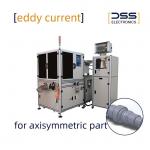

Eight Channels Microcomputer Controlled Eddy Current Flaw Detector Axisymmetric Part |

|

Automatic Bearing Roller Eddy Current Flaw Detector Large-scale Integrated Circuit |

|

Hardness Sorting Flaw Detection Synchronized Eddy Current Testing Machine Two Lines 4 Channels STY-2 |

|

Semi-automatic Analog Electronic Technology Digital Eddy Current Detector Cylinder Liner |