Intelligent Steel Non-destructive Sorting Instrument FET-II

|

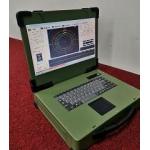

Product Description:FET-II type instrument is the upgraded product of steel material non-destructive testing instrument of our factory. The main heart by Intel 5p series monolithic computer as the main signal data processing, analysis and control, peripheral devices are used COMS small-scale integrated circuits, with low functional consumption, strong interference ability and other advantages.

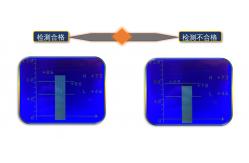

2. fast, accurate and convenient. (When testing just put the workpiece into the probe, the efficiency is dozens or even hundreds of times that of traditional testing methods. (For qualified and unqualified pieces have sound and light alarm function). 3. High sensitivity. (Different materials and heat treatment parts of the current and frequency continuously adjustable) 4. Simple operation. (The instrument is internally set up with man-machine dialogue function) 5. intuitive display. (Using microampere meter and digital tube double display can directly read the steel and hardness value) 6. Suitable for large quantities of testing needs, to ensure that product quality is foolproof. (can be used for raw materials and finished products for the full number of 100 test, rather than the conventional sampling test) 7. Light weight, AC and DC dual-use. (Instrument built-in 12V maintenance-free rechargeable battery, suitable for field operations) Technical Parameters:

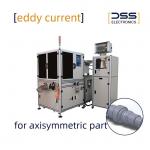

Applications:1. Magnetically conductive materials (e.g. wire, plate, pipe, strip, billet and various automotive parts, standard parts, bearing parts, forgings, cast steel parts, etc.) 2. Distinguish between steel grades and identify steel grades of the same size material. (Material rapid sorting) 3. hardness testing and fast differentiation of workpieces of the same size. (Quick sorting of hardness) 4. Carbon content of materials can be measured for carbon structural steel. (Carbon fixing) 5. Distinction and identification of defects in materials and heat-treated workpieces. (Flaw detection) 6. Identification and sorting of mechanical properties of materials and heat-treated workpieces. Support and Services:1. From the date of completion of installation and commissioning of the equipment, as the beginning of the quality assurance period of the equipment. The supplier will warranty the equipment for one year and implement lifelong maintenance service for the equipment. In the equipment warranty period of the relevant costs borne by the supplier, in the equipment warranty period of the relevant costs of the supply side only charge material costs.

FAQ:

|

||||||||||

| Product Tags: NDT eddy current flaw detector |

|

High Precision High Speed Eddy Current Testing Equipment Portable FET-GS18J |

|

Intelligent Digital Eddy Current Flaw Detector A Relatively Independent Test Channel |

|

High Resolution LCD Eddy Current Flaw Detector Square Oval Flat Shaped Matials |

|

Eight Channels Microcomputer Controlled Eddy Current Flaw Detector Axisymmetric Part |

|

Automatic Bearing Roller Eddy Current Flaw Detector Large-scale Integrated Circuit |

|

Hardness Sorting Flaw Detection Synchronized Eddy Current Testing Machine Two Lines 4 Channels STY-2 |