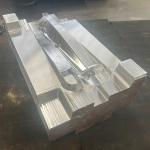

Zinc Alloy Die Casting Machine Components Polishing Anodizing,

|

Product Description:Die Casting Components is a range of precision-engineered products manufactured using advanced die casting technology. These components are made from both magnesium alloy castings and zinc alloy castings, as well as high-pressure die castings and aluminum alloy castings. The components come in a variety of sizes, all of which are customized to meet the specific requirements of the customers. The weight of the components range from 0.1 to 50kg, while the lead time for production is 7 to 15 days. The components can also be customized with additional features like CNC machining and surface treatments. The components are offered at competitive prices and the payment terms are also flexible. We accept payments through T/T, L/C, PayPal, etc. The components come with a 100% satisfaction guarantee and the customer service team is always available to answer any questions. Technical Parameters:

Applications:Ywy444 Die Casting Components are produced by high-pressure die castings, lost wax castings, zinc alloy castings and sand castings. Our die cast components are perfect for automotive, electronics, industrial applications and more. With our die casting components, your product can achieve a long-lasting, high-quality look. The size of the components can be customized according to your needs. Our die cast components are made from aluminum, zinc, magnesium, copper and other materials. The mold life of our die cast components is between 50,000 to 1,000,000 shots, and we offer multiple shipping options, including by sea, air, or express, to ensure that your product arrives on time and in the best condition. With Ywy444 Die Casting Components, you can rest assured that you are getting the highest quality components with superior performance. Customization:Customized Service for Die Casting Components

Support and Services:Technical Support and Service for Die Casting Components We provide our customers with comprehensive technical support and service for Die Casting Components. Design Optimization Our experts can help our customers to optimize their Die Casting Components designs for cost-efficiency and better performance. We adopt the latest technologies and manufacturing processes to ensure the best quality and cost-efficiency. Validation Tests We conduct thorough validation tests to ensure that our Die Casting Components meet the industry standards. Our tests include physical tests, chemical tests, and performance tests. Installation and Maintenance We provide installation and maintenance services for our Die Casting Components. Our technicians are experienced and knowledgeable in handling all types of Die Casting Components. We also provide ongoing after-sales services and maintenance. FAQ:

|

||||||||||||||||||||||

| Product Tags: Zinc Alloy Die Casting Machine Components Polishing Die Casting Machine Components |

|

Zinc Alloy Die Casting Machine Components Polishing Anodizing, |

|

High Precision Die Casting Components ±0.01mm Tolerance |

|

Automotive Die Cast Parts 3D 2D Drawing CNC Machining |

|

Customized Aluminum Die Casting Components 0-500T Pressure |

|

Processing Die Cast Aluminum Components Polishing Anodizing |

|

Aluminum Alloy Die Casting Components Electronics |