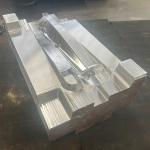

Product Description:

Die Casting Components are a versatile, cost-effective

manufacturing solution for a wide range of applications. Made from

aluminum, zinc, magnesium, copper and other metals, these

components are available in various shapes, sizes and weights.

Using advanced metal injection moldings, gravity castings and zinc

alloy castings, the components can be customized to meet the

specific needs of customers in automotive, electronics and

industrial sectors. With pressure ranging from 0-500T and weight

from 0.1-50kg, these components provide superior performance in

extreme temperature or environment.

Technical Parameters:

| Property | Description |

|---|

| Lead Time | 7-15 Days |

| Application | Automotive, Electronics, Industrial, Etc. |

| Size | Customized |

| Surface Finish | Polishing, Anodizing, Plating, Painting, Etc. |

| Mold Life | 50,000-1,000,000 Shots |

| Pressure | 0-500T |

| Package | Wooden Case/Pallet |

| Design | 3D/2D Drawing |

| Material | Aluminum, Zinc, Magnesium, Copper, Etc. |

| Tolerance | ±0.01mm |

| Die Casting Molds | Yes |

| Lost Wax Castings | Yes |

| Magnesium Alloy Castings | Yes |

Applications:

YWY444 Die Casting Components, a brand by YWY, are widely used in

Automotive, Electronics, Industrial, Etc. industries around the

world. These metal injection moldings, lost wax castings and die

casting molds feature a 0-500T pressure and are designed with 3D/2D

drawing technologies, providing superior quality and performance.

With a long mold life of 50,000-1,000,000 shots, these die casting

components are packaged in wooden cases or pallets for secure and

safe delivery.

Customization:

Customized Die Casting Components

Brand Name: YWY

Model Number: YWY444

Weight: 0.1-50kg

Place of Origin: Guangdong, Huizhou

Lead Time: 7-15 Days

Surface Finish: Polishing, Anodizing, Plating, Painting, etc.

Payment: T/T, L/C, PayPal, etc.

Processing: High-pressure Die Castings, Aluminum Alloy Castings,

Metal Injection Moldings, etc.

Support and Services:

Die Casting Components provide technical support and services to

ensure that our customers receive the highest quality parts. Our

services include:

- Design and engineering advice

- Mold design and construction

- Die casting process optimization

- In-house testing and certification

- Quality assurance and control

- Post-production support

We are committed to providing our customers with the best possible

service and support to ensure that their parts are produced to the

highest standards. Our team of experienced engineers and

technicians are available to provide technical assistance and

advice, as well as on-site testing and certification.

FAQ:

- Q: What is Die Casting Components?

- A: Die Casting Components is a product of ywy, with model number

ywy444 and place of origin guangdonghuizhou.

- Q: What are the advantages of Die Casting Components?

- A: Die Casting Components are more precise, repeatable and durable

compared with other casting methods. It is also cost-effective.

- Q: What materials can be used in Die Casting Components?

- A: Die Casting Components can be made of aluminum, zinc, magnesium

and other non-ferrous alloys.

- Q: What is the lead time of Die Casting Components?

- A: The lead time of Die Casting Components depends on the

complexity of the product and the quantity. Generally, it is about

15-30 days.

- Q: What is the minimum order quantity of Die Casting Components?

- A: The minimum order quantity of Die Casting Components is 1000

pieces.