Product Overview

The ceiling-ducted ventilation system is a modern overhead airflow

solution engineered for contemporary residential and commercial

settings. Featuring an innovative airflow channel design and

optimized circulation dynamics, this unit delivers whisper-quiet

operation while maintaining exceptional environmental comfort in

living spaces, offices, and retail establishments.

Key Features

- Enhanced Energy Efficiency

- Utilizes precision-engineered brushless motor technology for 40%

reduced energy consumption and vibration-free performance.

- Customizable 5-stage speed settings adapt to diverse airflow

demands, from gentle circulation to rapid ventilation.

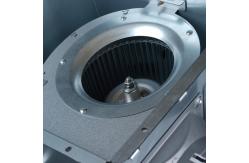

- Acoustic Optimization

- Aerodynamically refined blades combined with noise-dampening motor

housing achieve <25dB operation, equivalent to rustling leaves.

- Anti-resonance mounting system eliminates operational vibrations.

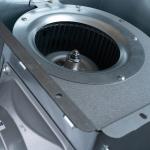

- Premium Construction

- Corrosion-resistant aluminum alloy housing with IP54-rated

durability for humid or dusty environments.

- Dual-layer thermal protection system automatically disengages power

during abnormal temperature fluctuations.

- Simplified Installation

- Modular components with pre-drilled alignment guides and tool-free

connectors enable 90-minute average installation time.

- Compatibility with standard 6"-12" circular ducting systems

(accessories included).

- Certified Safety

- ETL/CE-certified electrical system with automatic fault detection.

- Non-sparking motor design meets Class 1 Division 2 hazardous

location standards.

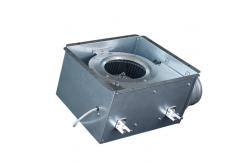

General assembly Drawing

Installation Protocol

Phase 1: Structural Preparation

Construct a robust rectangular framework using provided

corrosion-treated steel brackets, ensuring load-bearing compliance

with local building codes (minimum 50lb/sq.ft capacity).

Phase 2: Unit Integration

Mount the primary ventilation module to the pre-assembled support

structure using vibration-isolation fasteners (included),

maintaining 3" minimum clearance from combustible materials.

Phase 3: Ductwork Interface

Align the directional flow indicator on the duct collar with the

cabinet's exhaust port arrow mark. Engage the bayonet-style

coupling mechanism with a ¼ clockwise rotation until the safety

latch audibly clicks, confirming airtight sealing.

Product Performance Curve

Product Performance Specifications

Model Num | A | B | C | D | E | F | Cutout Dimensions |

BPT10-12 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT10-15 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT10-21 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT15-27 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-33 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-40 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-60 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |