Technical Overview

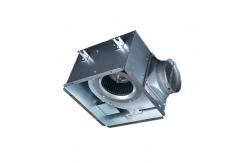

Engineered for commercial and residential climate optimization,

this ceiling-integrated air circulation system combines humidity

modulation (±5% RH precision), particulate filtration (PM2.5

capture rate: 92%), and odor neutralization (VOC reduction: 85%)

through aerodynamic blade geometry and multi-stage airflow

dynamics. Compliant with ASHRAE 62.1-2024 ventilation standards, it

achieves 6–12 air changes per hour (ACH) across spaces up to 4,000

ft³ (113 m³).

Performance Specifications

Engineering Advantages

- Fire-Safe Architecture

- Dual-layer 304-grade stainless steel housing with 1,200°F (649°C)

melt resistance.

- UL 2043-certified plenum rating for ceiling void installations.

- Energy-Optimized Drive

- IP55-rated ECM motor reduces power consumption by 38% vs.

traditional AC motors.

- Maintenance-free operation for 80,000+ hours (MTBF certified).

- Modular Service Design

- Tool-free cassette disassembly: Full component access in ≤90

seconds.

- Magnetic louver alignment system (8 design options, 6061-T6

aluminum).

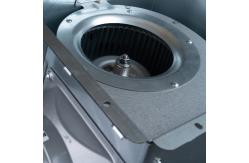

- Precision Airflow

- Forward-curved centrifugal impeller with dynamic balancing (G2.5

grade per ISO 1940).

- Symmetrical inlet/outlet ports eliminate turbulent losses (ΔP ≤15

Pa @ max airflow).

- Seismic-Resistant Mounting

- Galvanized steel framework (14-gauge, ASTM A653) with

vibration-dampened isolators.

- Pre-drilled anchor points for suspended ceilings (T-Bar or plaster

grid compatible).

General assembly Drawing

Product Installation Method

Phase 1: Structural Preparation

- Construct load-bearing frame using 1.5"×1.5" steel channels (min.

yield strength: 50 ksi).

- Secure to concrete ceilings via Hilti HY 150 epoxy anchors

(spacing: ≤16" OC).

Phase 2: Unit Integration

- Mount housing onto neoprene anti-vibration pads (included), torque

M10 bolts to 35 N·m.

- Align duct collar arrows with airflow direction; engage camlock

mechanism (audible click verification).

Phase 3: Post-Installation Validation

- Conduct anemometer test: Verify ±5% airflow uniformity across all

louvers.

- Perform infrared thermography to confirm motor winding temps ≤176°F

(80°C) at full load.

Sector-Specific Benefits

- Retail/Hospitality: Reduces HVAC energy costs by 22% through demand-controlled

ventilation.

- Healthcare: HEPA-compatible variant achieves ISO 14644-1 Class 8 cleanroom

standards.

- Residential: Integrates with Nest/ecobee thermostats for occupancy-based

airflow adjustment.

Product Performance Curve

Product Performance Specifications

Model Num | A | B | C | D | E | F | Cutout Dimensions |

BPT10-12 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT10-15 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT10-21 | 280 | 280 | 277 | 155 | 230 | 14 | 230*240 |

| BPT15-27 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-33 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-40 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |

| BPT15-60 | 380 | 380 | 341 | 224 | 306 | 14 | 306*306 |