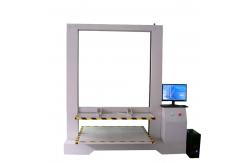

In the realm of quality control for packaging, precision and

reliability are non-negotiable. The Customized Intelligent Carton

Compression Testing Machine for Quality Control Laboratories is a

cutting-edge solution that empowers these facilities to ensure the

highest standards of carton integrity and performance. This state-of-the-art testing machine is purpose-built to assess

the compression resistance of cartons. Quality control laboratories

rely on it to verify that cartons meet the specified strength

requirements and industry standards. By subjecting cartons to

controlled compressive forces, it determines their maximum

load-bearing capacity and deformation characteristics, providing

crucial data for making informed decisions about the acceptability

of packaging materials and designs. - Sturdy and Durable Construction

- The testing machine features a robust steel frame that is designed

to withstand the rigors of continuous testing. The frame is

constructed from high-quality alloy steel, ensuring long-term

stability and minimal deflection. The columns and crossbars are

precision-engineered to maintain perfect alignment, which is

essential for accurate and repeatable test results. The base is

heavy and provides a solid foundation, reducing vibrations and

external influences during testing.

- Intelligent and User-Friendly Interface

- Equipped with an advanced touchscreen control panel, the machine

offers an intuitive interface for operators. They can easily input

test parameters such as compression speed, target load, and sample

dimensions. The system also allows for the creation and storage of

multiple test profiles, enabling quick access and execution of

different testing protocols. Real-time feedback is provided on the

screen, displaying the current load, displacement, and test

progress. Additionally, it can generate detailed test reports

automatically, saving time and effort in documentation.

- High-Precision Loading System

- The loading mechanism utilizes a servo-controlled motor and a

precision ball screw drive. This combination ensures extremely

accurate and smooth application of compressive force. The servo

motor allows for precise control of the loading rate, which can be

adjusted from a very slow and steady pace for detailed analysis to

a rapid rate for simulating more dynamic handling conditions. The

ball screw drive minimizes friction and backlash, resulting in

highly reliable and consistent force transmission.

- Accurate Sensing and Data Acquisition

- The machine is fitted with top-of-the-line load cells and

displacement sensors. The load cells have a wide measurement range

and an accuracy of within ±0.3% of the full scale, enabling precise

detection of even the slightest changes in load. The displacement

sensors offer a resolution of 0.005 mm, allowing for detailed

tracking of carton deformation. These sensors are connected to a

high-speed data acquisition system that records data at a rate of

up to 1500 samples per second. The collected data can be exported

in various formats for further analysis and comparison.

- Versatile Testing Capabilities

- It can accommodate a wide variety of carton sizes and shapes. The

testing platens are adjustable and can be configured to fit

everything from small, delicate cartons to large, heavy-duty ones.

The machine is capable of performing both static and dynamic

compression tests. Static tests provide information about the

carton's maximum load-bearing capacity under a steady force, while

dynamic tests can mimic the impacts and vibrations that cartons may

experience during transportation and handling. It can also be used

to evaluate the stacking strength of cartons, which is crucial for

warehouse storage scenarios.

- Maximum Load Capacity

- Available in models with capacities ranging from 200 kg to 20,000

kg, the machine can handle cartons of diverse strengths. For

example, a 200 kg capacity machine is suitable for testing

lightweight cartons used in the cosmetics or electronics

industries, while a 20,000 kg capacity model can assess the

robustness of heavy industrial packaging.

- Compression Speed Range

- The compression speed can be set from 0.05 mm/min to 1000 mm/min. A

slow speed like 0.05 mm/min is ideal for conducting detailed

studies of a carton's elastic and plastic deformation behavior. In

contrast, a speed of 1000 mm/min can simulate the rapid compression

that might occur in a high-speed packaging line or during rough

handling in transit.

- Accuracy of Load Measurement

- With an accuracy of ±0.3% of the full scale, the machine provides

highly reliable load measurements. This level of precision is

crucial for quality control laboratories, as it ensures that the

tested cartons meet the exact strength specifications. For

instance, if a carton is required to withstand a specific load

without failure, the accurate measurement can determine whether it

passes or fails the test.

- Displacement Measurement Resolution

- The 0.005 mm displacement measurement resolution allows for a

detailed understanding of how the carton deforms under load. This

information can be used to identify potential weak points in the

carton design and to optimize the packaging structure. For example,

it can help determine if a particular corner or seam is more prone

to failure and guide improvements.

- Testing Platform Dimensions

- The adjustable testing platform has a minimum size of 200 mm x 200

mm for testing small samples and can be extended up to 1500 mm x

1500 mm for larger cartons. This flexibility enables the testing of

a wide range of carton sizes commonly used in different industries.

- Rigorous Quality Assessment

- The primary function of the machine is to conduct accurate and

repeatable compression tests on cartons. It determines the maximum

compressive force a carton can endure before failure or excessive

deformation. This data is used by quality control laboratories to

ensure that cartons meet the required strength standards set by

regulatory bodies or customer specifications. For example, a food

packaging manufacturer can use the machine to confirm that their

cartons are strong enough to protect the contents during shipping

and storage.

- Design and Material Evaluation

- By testing different carton designs and materials, laboratories can

assess their relative strengths and weaknesses. The machine helps

in comparing the performance of various corrugated board types,

flute configurations, and paper qualities. This information is

invaluable for packaging designers and manufacturers looking to

optimize their products. For instance, they can determine which

combination of materials and design features provides the best

balance between cost and strength.

- Standard Compliance Verification

- Quality control laboratories use the machine to verify that cartons

comply with industry standards such as ISO, ASTM, or specific

customer requirements. It provides the necessary data to prove that

the packaging meets the required safety and durability standards.

For example, a company exporting products may need to demonstrate

that their cartons meet international shipping standards, and this

machine can generate the data for such compliance.

- Research and Development Support

- The testing machine also serves as a valuable tool for research and

development in the packaging field. It allows for the exploration

of new materials and innovative carton designs. Researchers can

study the effects of different additives, coatings, or structural

modifications on the compression strength of cartons. For example,

they can test the performance of bio-based packaging materials or

new folding techniques to improve carton strength.

- Stringent Manufacturing Process

- The Customized Intelligent Carton Compression Testing Machine is

manufactured under strict quality control guidelines. Each

component, from the steel frame to the sensors and control systems,

is sourced from reliable suppliers and undergoes thorough

inspection and testing. The assembly is carried out by highly

skilled technicians in a clean and controlled environment. The

machine is calibrated multiple times during the manufacturing

process using traceable reference standards to ensure its accuracy

and performance.

- Quality Certification and Validation

Our machine has obtained relevant quality certifications and has

been validated by independent testing laboratories. It has been

proven to provide accurate and reliable test results, conforming to

international and national standards for carton compression

testing. We also continuously update and improve our product based

on the latest technological advancements and customer feedback to

ensure its long-term performance and compliance.

- Food and Beverage Packaging

- A quality control laboratory for a major food and beverage company

used the testing machine to evaluate the cartons used for their

products. They discovered that a particular carton design had a

lower-than-expected compression strength, which could lead to

product damage during shipping. By making adjustments to the carton

structure and material, they were able to increase the strength by

25% and reduce the rate of damaged goods significantly.

- Pharmaceutical Packaging

- A pharmaceutical packaging quality control laboratory tested the

cartons used for drug shipments. The machine helped them identify a

batch of cartons with inconsistent compression strength. After

tracing the issue back to a manufacturing defect in the corrugated

board, they were able to work with the supplier to correct the

problem and ensure the integrity of the drug packaging.

- Consumer Goods Packaging

- A quality control lab for a consumer goods manufacturer used the

testing machine to compare different carton designs for a new

product line. They were able to select the most suitable design

based on the test results, which provided the best protection for

the products while also meeting cost and aesthetic requirements.

- Pre-Sales Technical Consultation

Our team of packaging testing experts offers in-depth technical

consultations to help quality control laboratories understand the

capabilities and suitability of the Customized Intelligent Carton

Compression Testing Machine for their specific testing needs. We

provide demonstrations and training, tailored to the laboratory

environment, to familiarize operators with the machine's functions

and operation before purchase. We also assist in selecting the

appropriate test methods and accessories based on the types of

cartons and testing requirements. - After-Sales Service and Maintenance

We offer comprehensive after-sales service, including on-site

installation and commissioning. Our technicians are available for

regular maintenance, calibration, and emergency repairs. We provide

spare parts and upgrades to keep the machine operating at peak

performance. We also offer service contracts that include

preventive maintenance and priority technical support, ensuring the

long-term reliability and availability of the testing machine for

quality control laboratories. - Training and Technical Support

We conduct training programs for new users to ensure they can

effectively operate the Customized Intelligent Carton Compression

Testing Machine and interpret the test results. Our technical

support team is available 24/7 to answer questions, provide

troubleshooting assistance, and offer guidance on test method

optimization and compliance with packaging testing standards. We

also provide software updates and support for the data acquisition

and analysis systems, enabling laboratories to take full advantage

of the latest features and technologies in carton compression

testing.

The Customized Intelligent Carton Compression Testing Machine for

Quality Control Laboratories is an indispensable tool for

maintaining the highest standards of packaging quality. If you are

a quality control laboratory seeking to enhance your carton testing

capabilities, ensure compliance with industry standards, or drive

innovation in packaging quality assurance, this is the ideal

solution. Contact us today to learn more and get a customized

quotation. Let us help you unlock the full potential of your

packaging quality control efforts. |