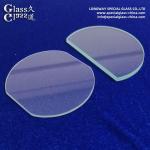

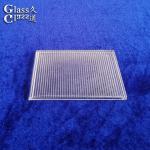

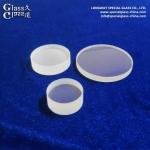

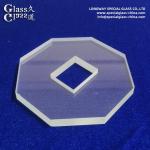

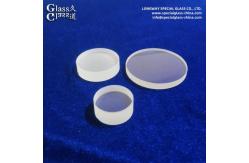

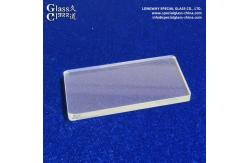

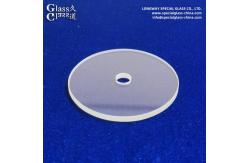

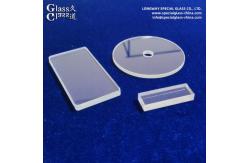

Custom Precision Borosilicate Glass Lenses In High-temperature

Industrial Sensors

Material: Core Composition: Engineered borosilicate glass,

primarily composed of silica (SiO₂ ~80%) and boron trioxide (B₂O₃

~13%), with additions of alkalis and aluminum oxide. Key Variants: Often Schott Borofloat® 33, Pyrex®-type, or

equivalent high-performance borosilicate formulations chosen for

specific thermal/chemical needs.

Key Properties: Exceptional Thermal Stability: Low Coefficient of Thermal Expansion (CTE): Typically ~3.3 x

10⁻⁶/K, minimizing dimensional change and stress under rapid or

extreme temperature fluctuations. High Thermal Shock Resistance: Withstands sudden temperature

changes (ΔT > 150°C) without cracking, critical for processes

like furnace entry/exit or quenching.

High Temperature Endurance: Maintains structural integrity and

optical clarity continuously at temperatures often exceeding 450°C,

with short-term peaks significantly higher. Chemical Durability: Highly resistant to water, acids,

alkalis, and solvents, preventing corrosion or clouding in harsh

industrial atmospheres. Optical Clarity & Transparency: High transmission across

relevant wavelengths (often visible to near-IR) essential for

accurate light signal transmission in sensors. Mechanical Rigidity & Hardness: Provides structural

stability and resistance to abrasion or particulate impact. Precision Manufacturability: Can be custom-ground and polished

to tight tolerances (surface figure, centration, thickness) for

specific optical requirements.

Primary Function: High-Temperature Optical Transmission Window: Acts as a

robust, clear barrier protecting sensitive internal sensor

components (detectors, electronics, optics) from extreme heat,

corrosive gases, dust, and pressure differentials. Precise Light Path Control: Ensures accurate transmission,

focusing, or collimation of light signals (e.g., infrared radiation

for pyrometry, laser beams for alignment, visible light for

inspection) within the sensor system, unaffected by thermal

distortion. Environmental Sealing: Forms a hermetic or near-hermetic seal

crucial for maintaining sensor calibration and protecting internal

electronics.

Critical Applications: Non-Contact Temperature Sensors (Pyrometers): Viewports and

focusing lenses directly exposed to molten metals (steel, aluminum,

glass), hot kilns, furnaces, reactors, and welding processes. Laser-Based Sensors: Windows and optics in laser distance

sensors, displacement sensors, and level sensors used in hot

environments like metal processing, glass manufacturing, and

semiconductor fabrication. Process Monitoring & Control: Lenses in cameras and

optical sensors for high-temperature industrial inspection (e.g.,

glass forming, metal casting, ceramic sintering, semiconductor

wafer processing). Combustion Monitoring: Optics in flame scanners and combustion

analyzers within boilers, gas turbines, and incinerators. Gas Analysis Sensors: Windows protecting optical cells in

Tunable Diode Laser Absorption Spectroscopy (TDLAS) and other

analyzers in hot, corrosive exhaust streams or process gases. Semiconductor Manufacturing: Optics in sensors for

lithography, etching, and deposition tools requiring thermal

stability and chemical purity.

Summary: Custom precision borosilicate glass lenses are vital components enabling reliable operation of industrial

sensors in extreme heat and harsh environments. Their unique

combination of ultra-low thermal expansion, high thermal shock

resistance, chemical durability, and optical clarity allows them to

function as robust, stable optical windows and precise

light-guiding elements. By protecting sensitive internals and

ensuring accurate signal transmission, these custom lenses are

essential for critical process control, safety monitoring, and

quality assurance in demanding industries like metals, glass, power

generation, chemicals, and semiconductor manufacturing.

| Name | Glass Lens, Glass disc, Sight glass | | Material | Pyrex, borosilicate glass, | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | by molding, grinding, polishing | | Working temperature | resisting high temperature shock | | Surface Quality | Optical grade | | Transmission | above 92% | | Chamfer | 0.1-0.3 mm x 45 degree | | Surface Coating | Available | | Usage | Optical system, Photographic sysem, Lighting system,Electronic

apparatus, |

|