Heat Strengthened Tempered Float Glass for Specialty Lighting

Material: Base Material: High-purity soda-lime silica float glass.

The float process ensures exceptional flatness, optical clarity,

and uniform thickness essential for lighting applications. Core Enhancement: Undergoes a specialized two-stage

thermal treatment process: Heat Strengthening: Glass is heated close to softening point

(~620-675°C) then cooled at a controlled rate faster than annealing

but slower than full tempering. This induces moderate surface

compression (typically 3,500-7,500 psi). Tempering (Fully Toughening): Subsequently heated again and

then rapidly quenched with high-pressure air jets. This

creates high surface compression (minimum 10,000 psi) and

balanced internal tension.

Key Properties: Enhanced Mechanical Strength: Significantly stronger than

annealed glass. Heat strengthening offers ~2x strength; full

tempering offers ~4-5x strength against impact and bending stress. Superior Thermal Resistance: Withstands high temperatures from

lighting sources (halogen, some LEDs) and rapid temperature changes

(thermal shock resistance) far better than annealed glass,

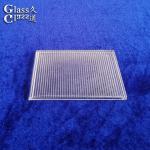

preventing thermal breakage. High Optical Clarity & Homogeneity: Maintains the

exceptional light transmission (>90%) and low distortion

inherent in float glass, crucial for precise light diffusion, color

rendering, and beam control. Safety: Tempering ensures safety. If broken, it fragments

into small, relatively blunt granular pieces ("dice") instead of

large, sharp shards, reducing injury risk. Flatness & Stability: The float base combined with

controlled thermal processing ensures excellent dimensional

stability and flatness, critical for optical components and fixture

integration. Durability: Resists scratches and surface damage better than

annealed glass during handling and use.

Primary Function: To serve as a high-performance, safe, and optically superior

glazing component specifically engineered for demanding

lighting environments. Provides structural integrity to withstand thermal and

mechanical stresses inherent in luminaires. Ensures optimal light transmission and minimal

distortion for accurate lighting performance. Acts as a critical safety barrier by containing glass

fragments if breakage occurs.

Main Applications (Specialty Lighting Focus): High-Output Architectural Luminaires: Recessed downlights,

track heads, wall washers, where heat buildup is significant. Stage & Studio Lighting: Lenses, color filter holders, and

protective covers for hot, high-intensity lamps (e.g., Fresnels,

PAR cans). Industrial & Commercial Lighting: High-bay fixtures,

machine vision lighting, UV curing lamps requiring thermal

stability. Transportation Lighting: Headlamp lenses (outer covers or

internal elements), signal lights, interior cabin lighting panels

requiring strength and safety. Decorative & Feature Lighting: Glass shades, diffusers, or

structural elements in designer pendants, chandeliers, and custom

fixtures needing both aesthetics and resilience. Projection & Optical Systems: Lenses, prisms, or

protective windows where clarity, flatness, and thermal stability

are paramount.

In essence: Heat Strengthened Tempered Float Glass for Specialty Lighting is engineered float glass subjected to sequential thermal

treatments (heat strengthening followed by full tempering). This

process grants it significantly increased strength,

exceptional thermal shock resistance, and critical safety

fragmentation, while preserving the high optical clarity and

flatness of the base float glass. It is the material of choice for

demanding lighting applications – from architectural and stage

lights to transportation and decorative fixtures – where exposure

to heat, mechanical stress, and the need for precise, safe light

transmission are fundamental requirements.

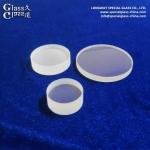

| Item | Tempered glass | | Material | Borosilicate glass, Float glass | | Diameter Tolerance | +0/-0.5 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | By Molding and Polishing | | Working temperature | Resisting high temperature shock | | Surface Quality | Clear and smooth | | Transmission | Around 90% for visible light | | Tempering | Available | | Usage | Lighting system and Optics etc. |

|