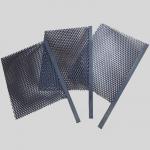

MMO Mesh Ribbon Anode

MMO mesh ribbon anode is manufactured from an expanded titanium

mesh substrate coated with mixed metal oxides. The mixed metal

oxide coating, with industrially proven lifetime characteristics,

ensures an even current distribution along the anodes length.

- Quality Substrate Material

The titanium substrate of the anode is selected according to ASTM

B265 Grade 1 standard requirements. The high purity titanium has

proven excellent chemical corrosion resistance, low electrical

resistance, and high mechanical integrity against damage.

- Noble Metal Oxide Coating

The Ir–Ta (IrO2/Ta2O5) mixed metal oxide catalyst, sintered to the

surface of titanium substrate, demonstrates high chemical stability

when exposed to high current density. We are able to produce anodes

with differing coating thickness and noble metal oxide ratios.

Strict quality procedures are followed throughout the coating

process to ensure appropriate coating thickness and adhesion.

Specifications of MMO Ribbon Anode

The MMO Ribbon Anode specifications are meticulously designed to

cater to diverse corrosion protection requirements. The table

presents a clear breakdown of the parameters:

Width(mm) | Thickness(mm) | Length(m) | Current

output(mA/m) | Expected life(a) |

6.35 | 0.635 | 152 | 17 | 50 |

10 | 1.3 | 76 | 2.8 | 75 |

13 | 1.3 | 76 | 3.5 | 75 |

19 | 1.3 | 76 | 5.28 | 75 |

Applications of MMO Ribbon Anode

MMO Ribbon Anodes are widely utilized in various infrastructures

across multiple sectors to ensure optimal cathodic protection.

Notable applications encompass:

Reinforced Concrete Structures: These anodes are adept at shielding

reinforced concrete assets against the deleterious effects of

environmental elements like chlorides and carbonation. Structures

such as bridges, parking facilities, and commercial edifices often

benefit from their integration.

Subterranean Steel Constructs & Pipelines: The MMO Ribbon Anode

proves instrumental in preventing corrosion in steel structures and

pipelines that are buried, defending them from the corrosive

tendencies of soil and ambient moisture. Depending on the need,

they can be arrayed in continuous horizontal beds or vertically at

shallow depths.

Storage Tanks (Subsurface & Surface): For both underground and

above-ground storage reservoirs, these anodes provide a robust

defense mechanism against corrosion on tank bottoms and sides.

Their flexibility allows for both vertical and horizontal

placements, adapting to the tank’s structural nuances.

Bridge Infrastructure: Vital components of bridges, such as piers

and abutments, often face corrosion challenges from elements like

saltwater. MMO Ribbon Anodes, in such scenarios, serve as a

protective layer, ensuring the longevity and structural integrity

of these bridge components.