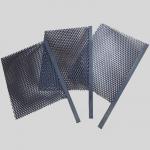

Ruthenium-Based MMO Coated Titanium Anode Ruthenium-based Mixed Metal Oxide (MMO) titanium anodes are widely

used to enhance the corrosion resistance and stability of anodes.

According to the classification of gases evolved in electrochemical

reactions, insoluble anodes can be divided into three types:

chlorine evolution type, oxygen evolution type, and combined

chlorine and oxygen evolution type. The ruthenium oxide coated

titanium anodes belong to the chlorine evolution type and exhibit

outstanding performance in related processes. Specifications of Ruthenium-based MMO titanium anodes- Substrate: TA1/TA2

- Coating:Pure ruthenium, ruthenium-iridium, ternary

ruthenium-iridium, multicomponent ruthenium-iridium mixed oxide

formulations

- Operating Environment: Generally used in hydrochloric acid,

electrolyzed seawater, and electrolyzed brine environments

- Dimensions: Customized according to requirements

- Shape: Plate, mesh, tubular

- Current Density: ≤ 1000 A/m2

- Expanded mesh technical data

Overall Thickness | Design Size (in.) | Opening Size (in.) | Strand Size (in.) | | | SWD | LWD | SWO | LWO | Width | Thickness | | .050 | .140 | .280 | .085 | .185 | .029 | .024 | | .070 | .165 | .400 | .115 | .260 | .035 | .024 | | .060 | .230 | .500 | .170 | .370 | .036 | .024 | | .083 | .220 | .400 | .140 | .240 | .035 | .024 | | .085 | .220 | .400 | .140 | .240 | .045 | .030 | | .080 | .270 | .600 | .200 | .440 | .045 | .024 | | .088 | .270 | .600 | .200 | .440 | .050 | .030 | | .172 | .630 | 1.575 | .428 | 1.260 | .110 | .060 |

Features of Ruthenium-based MMO titanium anodes - The coating can be customized with different formulations for

various operating environments. The improved nanoscale refined

grains enhance the bonding between the coating and the substrate,

leading to better electrocatalytic performance.

- The chlorine evolution overpotential is reduced, which extends the

electrode's service life and provides good corrosion resistance.

- The size and shape of the anode can be customized based on actual

working conditions to meet specific needs.

- Anode recoating services are available based on the wear of the

anode coating. The substrate can be reused multiple times without

excessive wear, saving costs for the user.

Ruthenium-based MMO titanium anodes Application Fields - Non-ferrous metal electrolytic production

- Chlor-alkali electrolysis

- Seawater electrolysis

- Manufacture of metal foils

- Electrochemical surface treatment of metal foils

- Electrolytic extraction and recovery of non-ferrous metals

- Organic electrolysis

- Cathodic protection

- Electrodialysis

- Production of acidic and alkaline ionized water

- Industrial wastewater treatment and other fields.

|