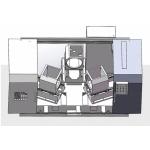

Fire Hydrant Flange Processing High-precision Three-sided Multi-hole Drilling Machine

|

|

Swing Angle Three-sided Multi-hole Drilling Machine

The swing angle three-sided multi-hole drilling machine is a CNC machine tool specially used for multi-sided drilling processing. It can handle multiple drill bits at the same time, greatly improving the drilling efficiency. The equipment adopts advanced CNC system and precise transmission mechanism to ensure the accuracy and consistency of drilling. Whether it is a single hole or multiple holes, it can meet extremely high precision requirements.

Main features

Components

Application

Details

|

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Fire Hydrant Flange Drilling Machine Multi-Hole Drilling Machine | |||||||||||||||||||||||||||||||||||||||||||

|

High-precision Three-sided Multi-hole Drilling Machine For Fire Hydrant Car Rear Axle Valve |

|

Fire Hydrant Flange Processing High-precision Three-sided Multi-hole Drilling Machine |

|

Three Sided Multi Hole Drilling Machine For Non Standard Valve And Pipe Fittings |

|

Rotary U Drilling CNC Drill Machine Φ340 Maximum Workpiece |

|

Gate Valve Butterfly Valve Heck Valve Multi Hole Drilling Machine Single Sided |

|

Swing Angle Three Sided Cnc Multi Boring Machine Lathe 4000KG |