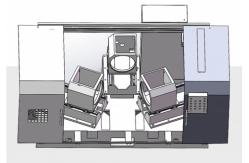

Swing Angle Three Sided Cnc Multi Boring Machine Lathe 4000KG

|

|

Swing Angle Three-sided CNC Boring Lathe

The swing angle three-sided multi-hole drilling machine is a CNC machine tool specially used for multi-sided drilling processing. It has the ability to work with multiple drills at the same time, which can greatly improve the drilling efficiency. The equipment adopts advanced CNC system and precise transmission mechanism to ensure the accuracy and consistency of drilling. Whether it is a single hole or multiple holes, it can meet extremely high precision requirements.

Main features 1. Efficiency: The swing angle three-sided multi-hole drilling machine has the ability to work with multiple drills at the same time, which can greatly improve the drilling efficiency. In addition, its fast tool change system reduces the waiting time during the processing, further improving production efficiency. 2. Accuracy: The equipment adopts advanced CNC system and precise transmission mechanism to ensure the accuracy and consistency of drilling. Whether it is a single hole or multiple holes, it can meet extremely high precision requirements. 3. Flexibility: The swing angle three-sided multi-hole drilling machine can be personalized according to different processing needs, such as adjusting the number of drills, replacing different types of drills, etc. This flexibility enables the equipment to adapt to various complex drilling scenarios. 4. Versatility: The swing angle three-sided multi-hole drilling machine is not limited to drilling, but can also perform diversified operations such as milling long slots and tapping. The fully digital control system ensures high-precision processing, while simplifying the operation process and improving efficiency. 5. Structural design and ease of operation: The swing angle three-sided multi-hole drilling machine has a reasonable structural design and good rigidity, and can maintain stable performance at high speeds. This not only helps to extend the service life of the equipment, but also ensures the safety and reliability of the processing process.

Main components 1. Bed: The solid structure is made of high-quality materials such as high-strength cast iron, which gives it excellent rigidity and stability. This design can cope with various loads during the processing and ensure stability under conditions such as cutting force, gravity and vibration. 2. Spindle: The design has multiple spindles, which can process multiple faces of the workpiece at the same time, greatly saving processing time. 3. Worktable: Used to fix the workpiece, it can usually rotate or move to meet different processing requirements. 4. Control system: Advanced CNC system, responsible for programming and controlling the processing process.

Application areas 1. Casting valves: various valves, such as gate valves, butterfly valves, check valves, etc. 2. Casting water pumps: water pumps of various calibers and shapes. 3. Firefighting industry: water supply and drainage facilities such as fire hydrants. 4. Pipe fittings industry: various flange elbow pipe fittings.

Details

Processed product

|

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: three sided cnc multi boring machine 4000kg cnc multi boring machine 4000kg multi spindle cnc drilling machine | |||||||||||||||||||||||||||||||||||||||||||

|

Time-saving Labor-saving High-precision Three-sided Valve Water Pump Fire Hydrant Multi-hole Drilling Machine |

|

High-precision Three-sided Multi-hole Drilling Machine For Fire Hydrant Car Rear Axle Valve |

|

Three Sided Multi Hole Drilling Machine For Non Standard Valve And Pipe Fittings |

|

Rotary U Drilling CNC Drill Machine Φ340 Maximum Workpiece |

|

Gate Valve Butterfly Valve Heck Valve Multi Hole Drilling Machine Single Sided |

|

Swing Angle Three Sided Cnc Multi Boring Machine Lathe 4000KG |