In industrial milling and grinding, the choice of media can

significantly impact efficiency, cost, and product quality. Among

the array of options, high-strength zirconia toughened alumina

(ZTA) grinding balls stand out as a superior choice for their

exceptional wear resistance, mechanical strength, and

versatility.

Zirconia toughened alumina grinding balls are an advanced ceramic

composite made by combining alumina and zirconia. This combination

results in a material that exhibits the hardness and wear

resistance of alumina while benefiting from the enhanced toughness

provided by zirconia. The synergy of these materials creates a

grinding media that is not only durable but also versatile, capable

of performing in both wet and dry grinding processes.

1. Superior Wear Resistance:

ZTA grinding balls are renowned for their outstanding wear

resistance. According to research and industrial tests, they offer

2-15 times better wear resistance compared to conventional high

alumina media. This translates into longer service life and reduced

downtime, ultimately saving costs.

2. High Mechanical Strength and Toughness:

The integration of zirconia into the alumina matrix enhances the

mechanical strength and fracture toughness of the grinding balls.

This makes them suitable for high-impact grinding applications,

where other media might fail.

3. Versatile Applications:

ZTA grinding balls are used across a wide range of industries,

including ceramics, mining, metallurgy, and chemicals. They are

particularly effective in the ultra-fine grinding of high-hardness

materials such as dyes, coatings, electronic materials, and lithium

battery raw materials.

4. Chemical and Thermal Stability:

These grinding balls exhibit excellent resistance to acids,

alkalis, and high temperatures, making them ideal for environments

where chemical stability is crucial.

1. Ceramics Industry:

In the ceramics industry, ZTA grinding balls are used for milling

ceramic bodies, glazes, and zircon. Their high wear resistance

ensures minimal contamination of the product, maintaining the

integrity of the final ceramic pieces.

2. Mining and Metallurgy:

ZTA balls are extensively used in the grinding of precious metals

like gold, silver, and platinum, as well as base metals such as

copper and lead. Their ability to withstand harsh milling

conditions makes them invaluable in these sectors.

3. Chemical Industry:

In chemical processing, ZTA grinding balls are employed in the

production of pigments, paints, and coatings. Their chemical

inertness ensures no unwanted reactions occur during milling,

preserving the quality of the end product.

4. Electronics and Energy Storage:

The electronics industry benefits from ZTA grinding balls in the

production of components like resistors, capacitors, and polishing

pastes. Additionally, they are crucial in the preparation of

lithium battery materials, where purity and precision are

paramount.

1. Cost-Effectiveness:

Despite their higher initial cost, ZTA grinding balls offer a

superior performance-price ratio. Their durability and efficiency

reduce the frequency of replacement and maintenance, leading to

long-term savings.

2. Environmental and Safety Benefits:

ZTA grinding balls are non-toxic and pollution-free, making them

suitable for industries where contamination must be avoided, such

as food and pharmaceuticals.

3. Customization and Flexibility:

We offer customization options, allowing clients to tailor the

size, purity, and composition of the grinding balls to specific

applications. This flexibility ensures optimal performance in

diverse operational settings.

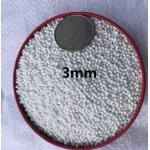

●Sizes Φ:

| Size(mm) | Size(mm) | Size(mm) | Size(mm) |

| 0.5-1.0 | 6.0 | 20.0 | 70.0 |

| 1.0 | 8.0 | 25.0 | 80.0 |

| 2.0 | 10.0 | 30.0 | 90.0 |

| 3.0 | 13.0 | 40.0 | 100.0 |

| 4.0 | 15.0 | 50.0 |

|

| 5.0 | 18.0 | 60.0 |

|

●Package:

25KG/woven bag,1000KG-1250KG for one pallet with shrink wrapped