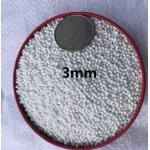

High Density 92% Ceramic Alumina Ball Media For Industrial Applications

|

|

92% Ceramic Alumina Ball ●Chemical Composition:

●Typical Properties:

● Sizes Φ:

● Features: u High density, high hardness, low wear loss, regular shape, impact resistance, corrosive resistance; u 20-40times wear-resistance more than natural ball and common ball, and can improve 40--60% grinding efficiency.

● Applications: u High hardness and high viscosity material, such as zircon sand, silicon dioxide, calcite (GCC), magnetic bands coatings for audio and video tapes, paint, coating, pigment, Ceramic glaze, titanium dioxide and so on. u Wet grinding including batch mill and continuous ball mill.

●Package: 25KG/woven bag,1000KG-1250KG for one pallet with shrink wrapped |

||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: High density Alumina Ball media industrial Ceramic Alumina Ball media 92% Ceramic Alumina Ball media |

|

2000MPa High Al₂O₃ Alumina Oxide Balls For Anode Cathode Processing |

|

Pharma Grade Alumina Grinding Balls Ceramic Milling Media GMP Compliant For Drug Manufacturing |

|

Low Sodium 92% Alumina Ball Aluminum Oxide Ceramic Balls For Battery Material Processing |

|

High Density 92% Ceramic Alumina Ball Media For Industrial Applications |

|

Alumina Grinding Balls Aluminum Oxide Grinding Wheels Durability And Cost-effectiveness |

|

92% Al2O3 High-Alumina Ceramic Grinding Balls Non-ferrous Metals |